PROTOTYPING SUPPORT

CNC MACHINED PROTOTYPES, SAMPLE RUNS & PRE PRODUCTION BUILDS

We manufacture CNC machined prototypes and sample builds for engineered products, hardware development and OEM applications, with support through pre production and batch supply.

Ideal for teams validating fit, function and assembly before moving into repeat manufacture.

PROTOTYPING CAPABILITIES

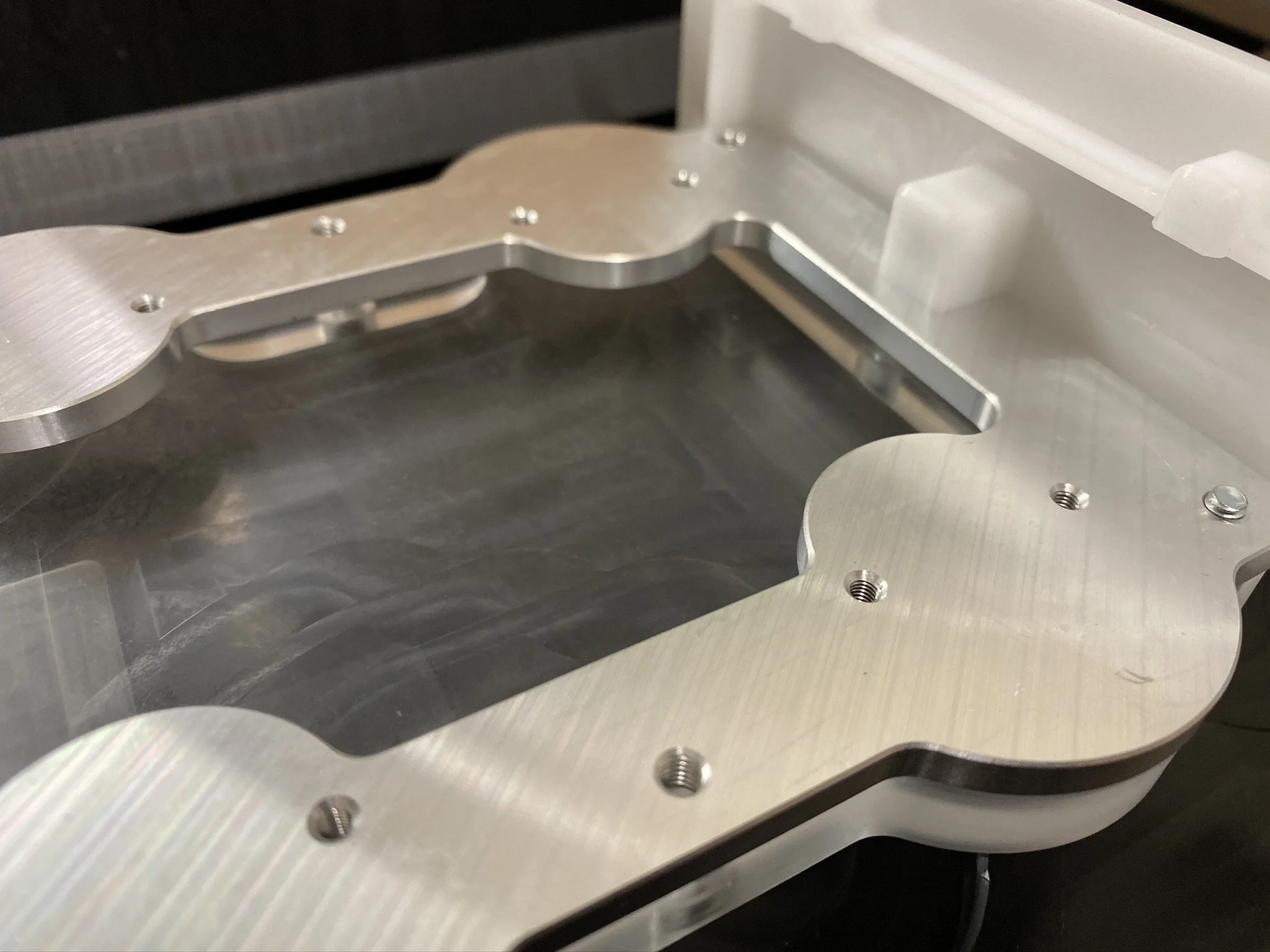

CNC MACHINED PROTOTYPES

Aluminium, brass and engineering plastics machined for hardware, lighting and product development.

SAMPLE & PRE PRODUCTION BUILDS

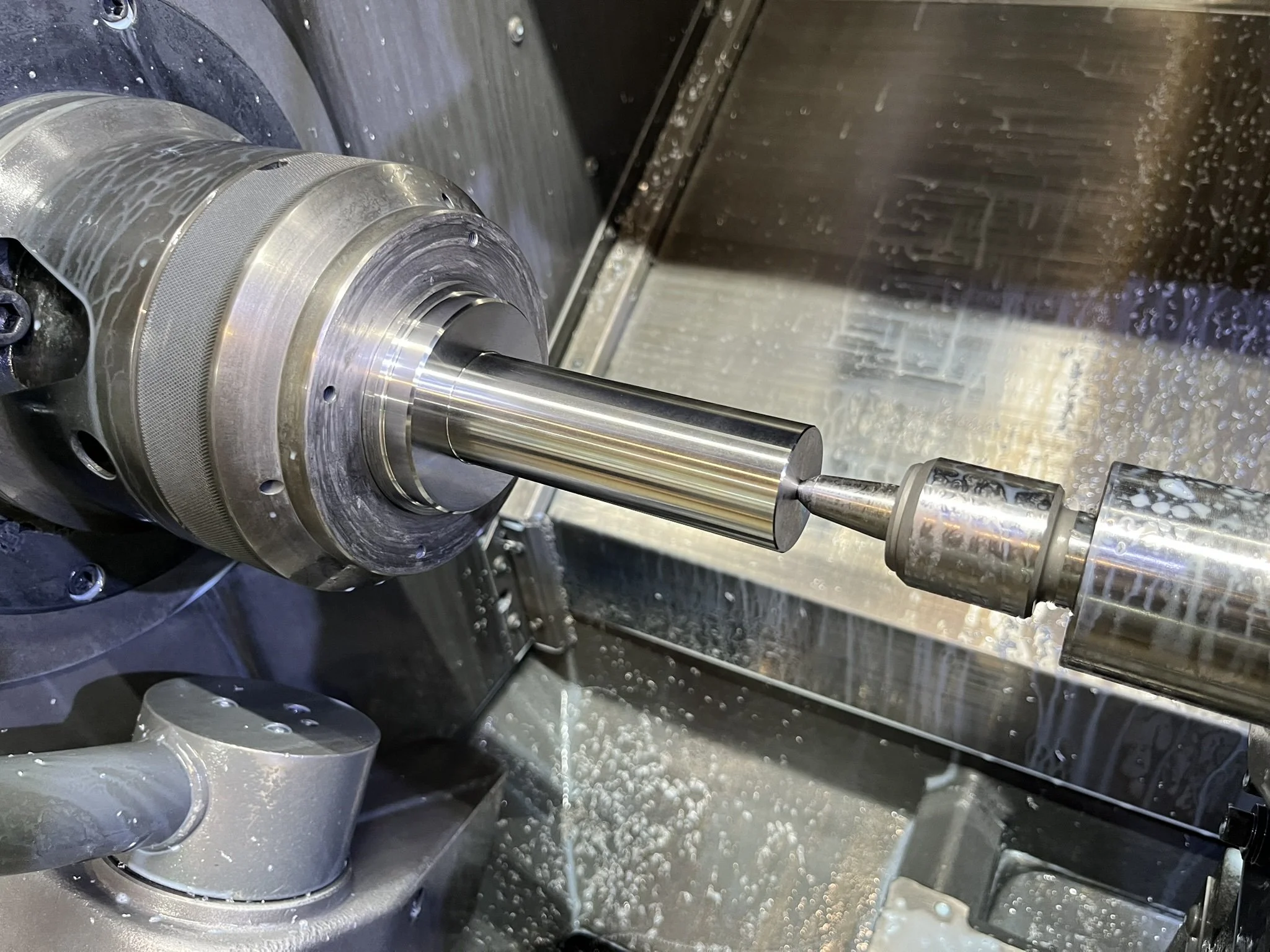

One off prototypes and sample builds for validating fit and function before pre production and batch supply.

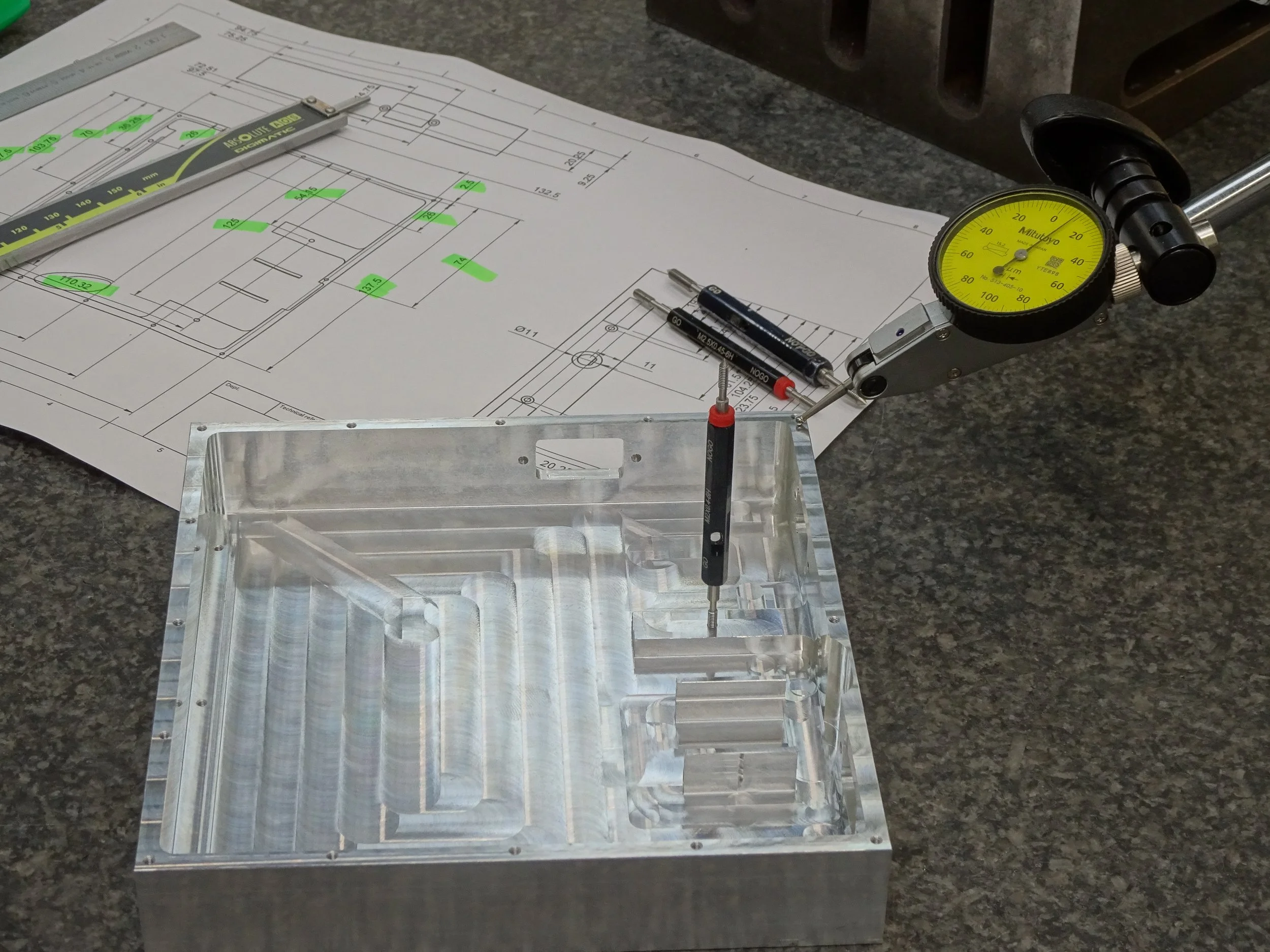

DESIGN FOR MANUFACTURE (DFM)

Feedback on geometry, material and machining approach to reduce cost and lead time.

BATCH TRANSITION SUPPORT

Support for moving from prototype to batch supply, including fixture development and QA.

INDUSTRIES WE SUPPORT

Lighting OEM

Horticultural & grow lighting OEM

Hardware product development

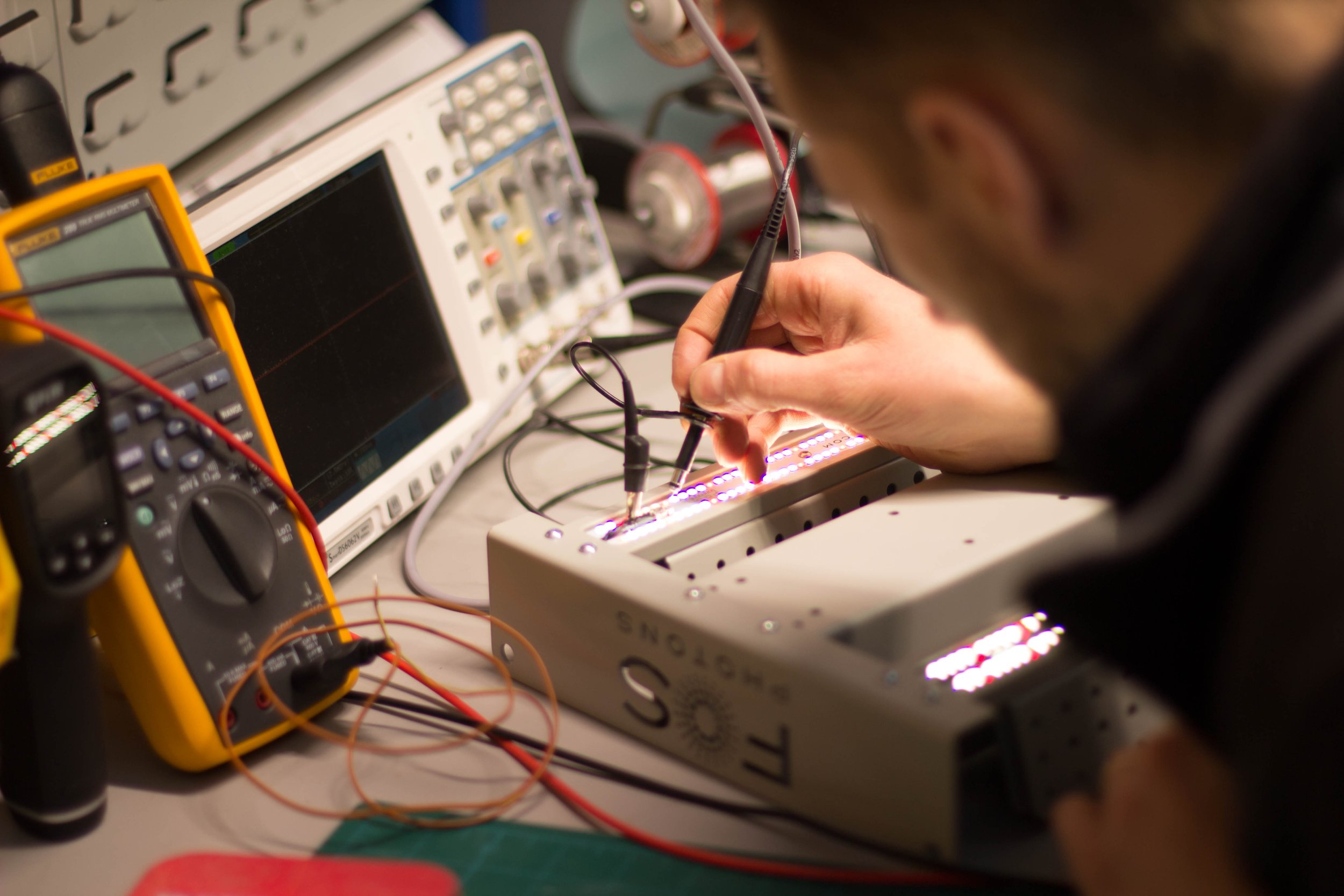

Robotics & automation

Instrumentation & sensing

Electro-mechanical assemblies

R&D & test rigs

Sample & pilot builds

WHAT TO SEND

DRAWINGS OR CAD FILES (STEP, DXF or PDF)

QUANTITIES

(prototype, sample or pre-production)

MATERIALS

(aluminium, brass or plastics)

NOTES

(tolerances, mounting or finishing)

If you’re earlier in the design process, feel free to send what you have, we’re happy to review.

DETAILS THAT HELP WITH QUOTING & PROTOTYPING

-

CNC machined prototypes and sample builds for hardware, lighting and OEM applications. Ideal for validating fit, function and assembly before pre-production.

-

Yes, prototypes can progress into pre-production and batch supply, including fixture development and process refinement where required.

-

Aluminium, stainless steel, brass and egineering plastics.

-

Yes, we can prepare or refine CAD and drawings as part of a machining engagement, including DFM adjustments. Standalone CAD or design only work is handled by the customer or design partner.

-

Yes, 3D printing can be used for early fit checks or fixtures, before CNC machining for functional prototypes and pre-production parts.

-

Light assembly and fit checks are possible when we manufacture the components. Full product assembly and compliance testing are handled by the customer.

-

Finishing can be arranged on request. Many customers handle finishing within their own supply chain for pilot and pre-production builds.

-

We are based in Hertfordshire and supply prototypes and batch parts across the UK.

MORE UNDER ONE ROOF

Based in Hertfordshire, we provide CNC milling, CNC turning, laser cutting, laser marking and finishing support for prototype, small batch and repeat production across the UK.

Machined aluminium, brass and plastics for functional prototypes and sample builds. Ideal for validating fit, geometry and assembly before pre-production.

Turned components for electro-mechanical, lighting and hardware assemblies, with prototype quantities supporting later batch supply.

Batch and prototype marking for identification, traceability and branding. Useful for sample kits, R&D parts and pilot builds.

Laser cut plastics and optical panels for enclosures, diffusers and packaging inserts, with fast iteration for development and sample runs.

READY TO GET A PROTOTYPE MADE?

Send us your drawing or CAD file and we’ll review it, ask any questions, and come back to you with next steps.