HOW WE MAKE PARTS

This page shows real work from our workshop, capturing how parts move from raw material through machining, finishing and inspection. All images on our website are taken by us, and reflect day to day production, not staged photography.

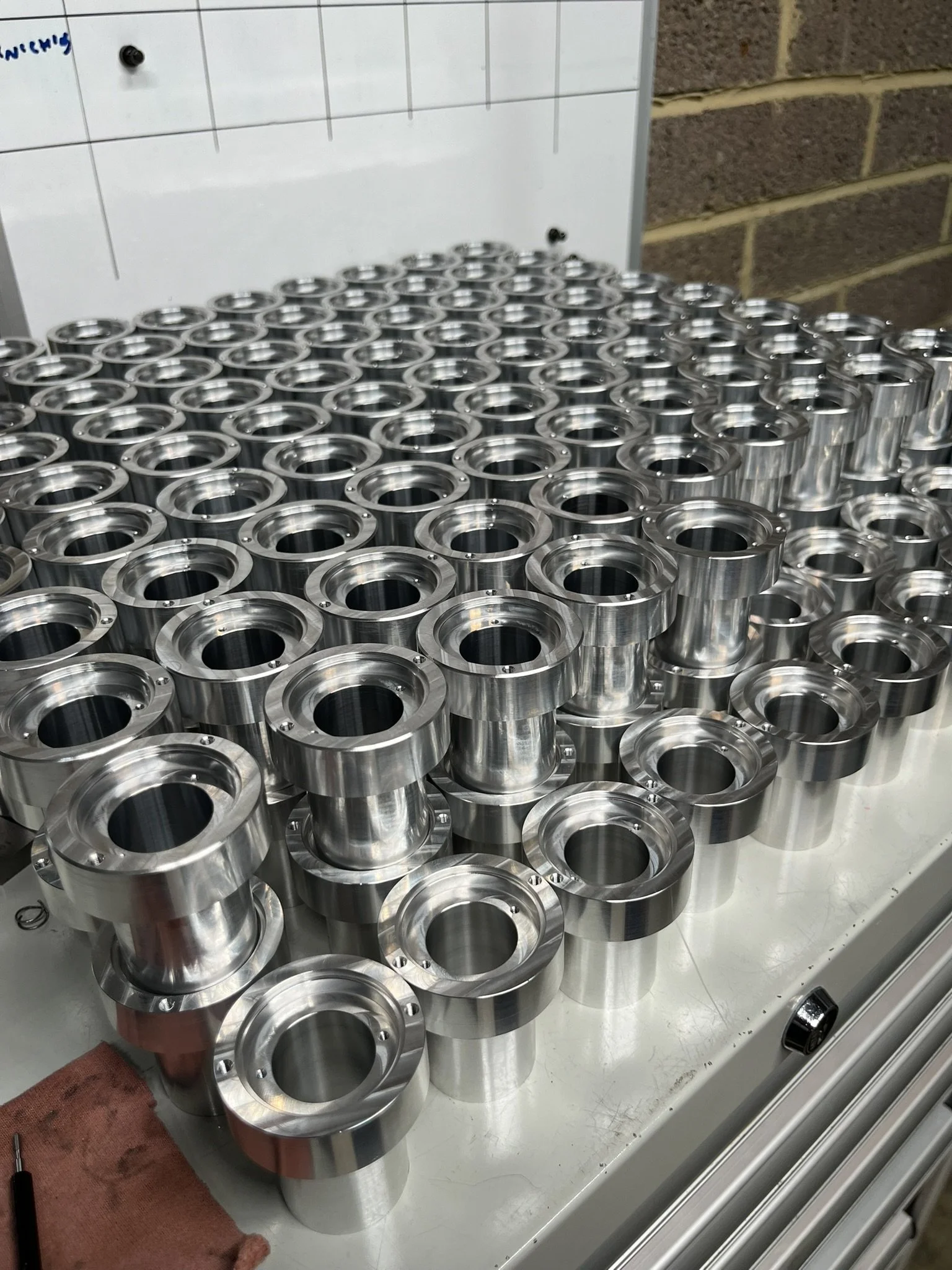

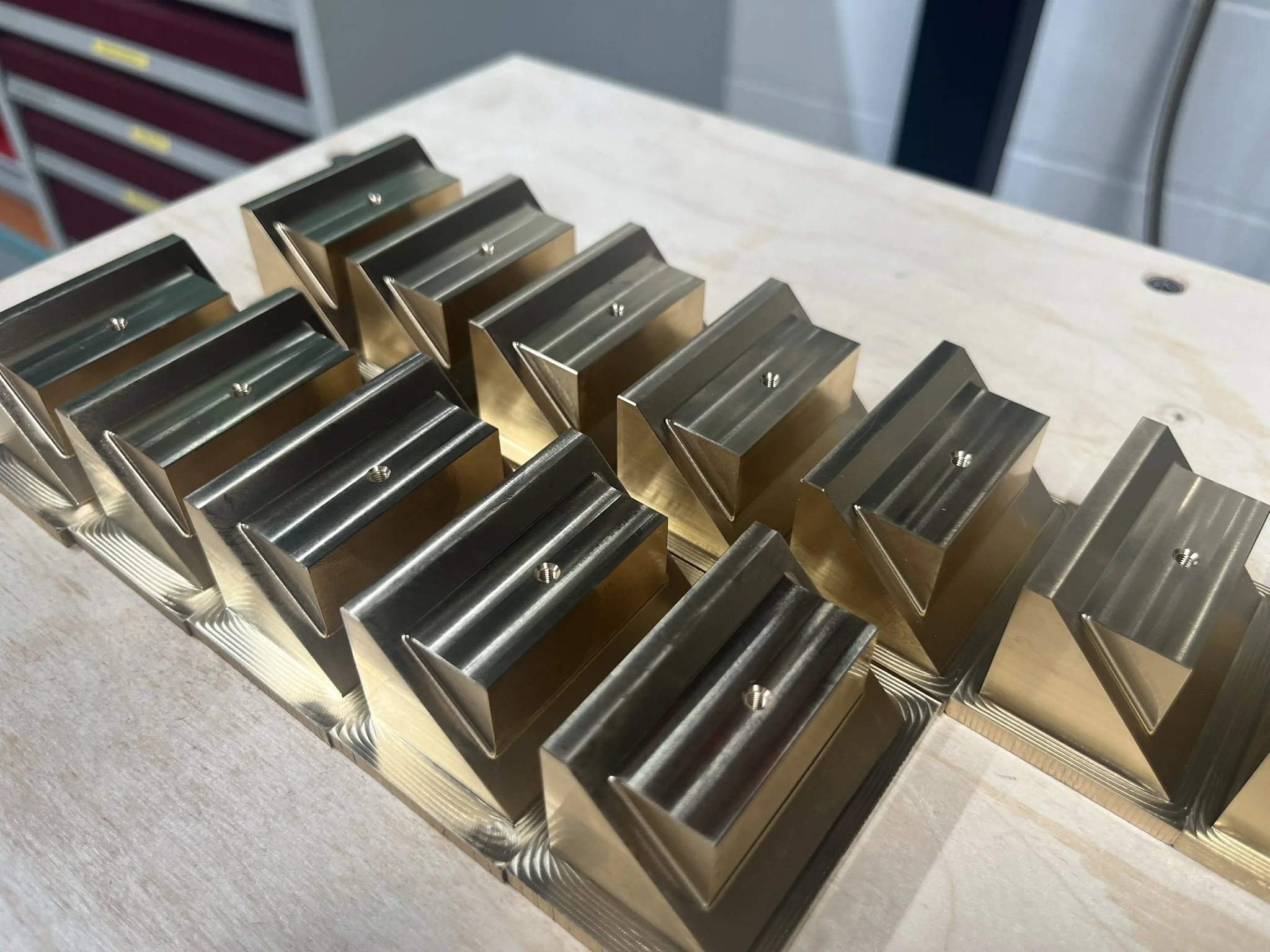

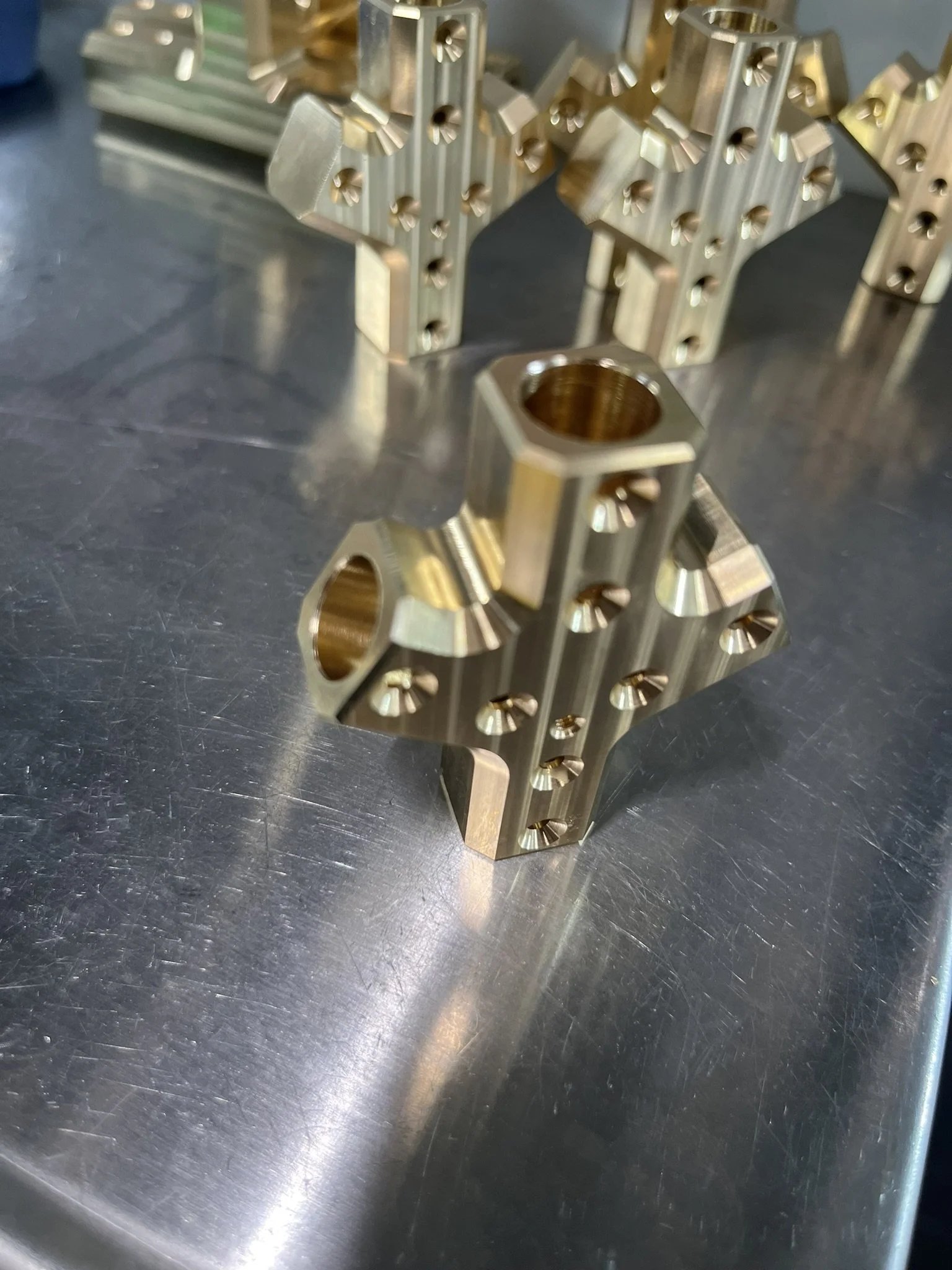

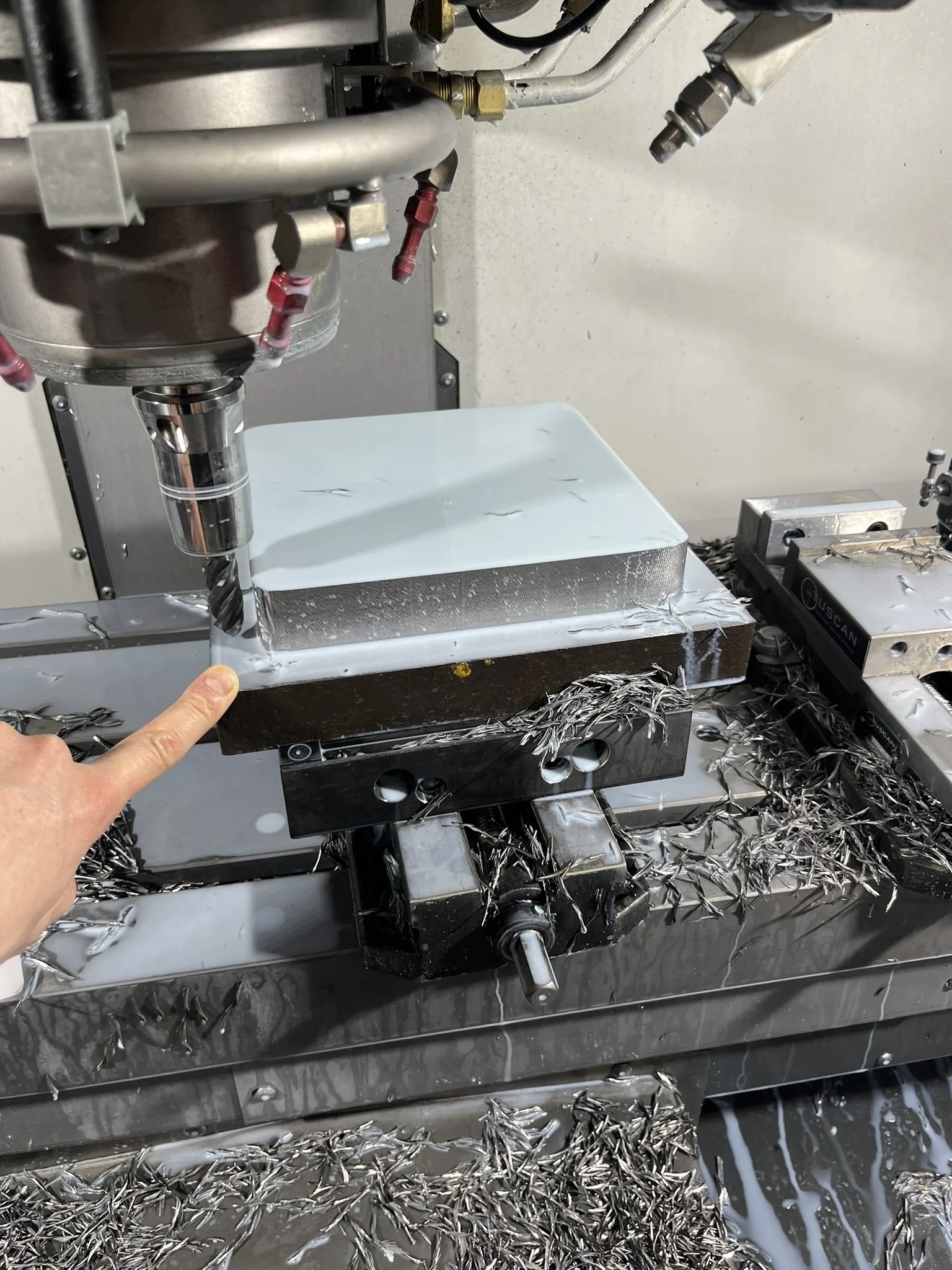

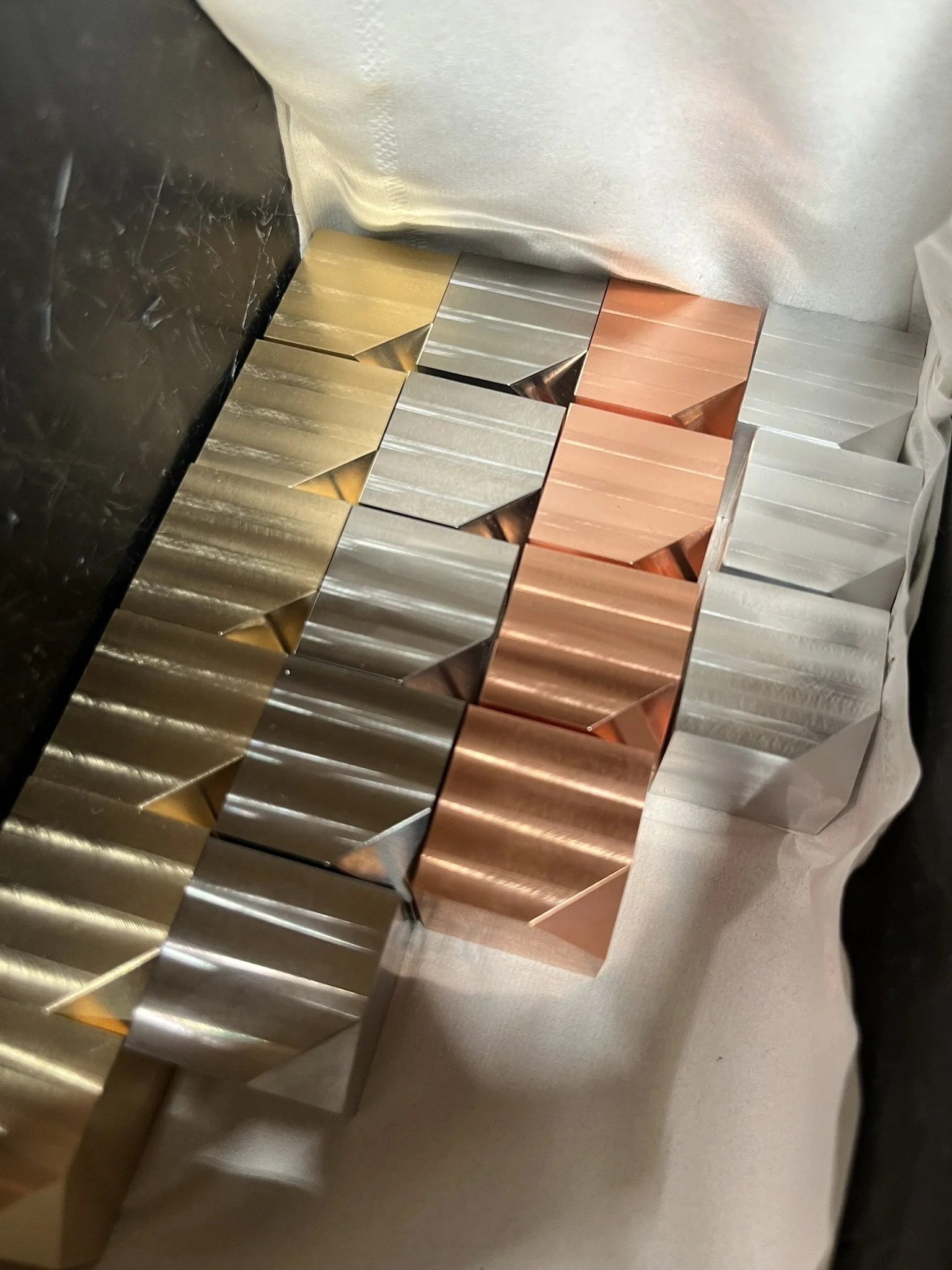

AFTER MACHINING

Parts can be deburred in our vibratory tumbler to remove sharp edges and achieve a consistent surface finish.

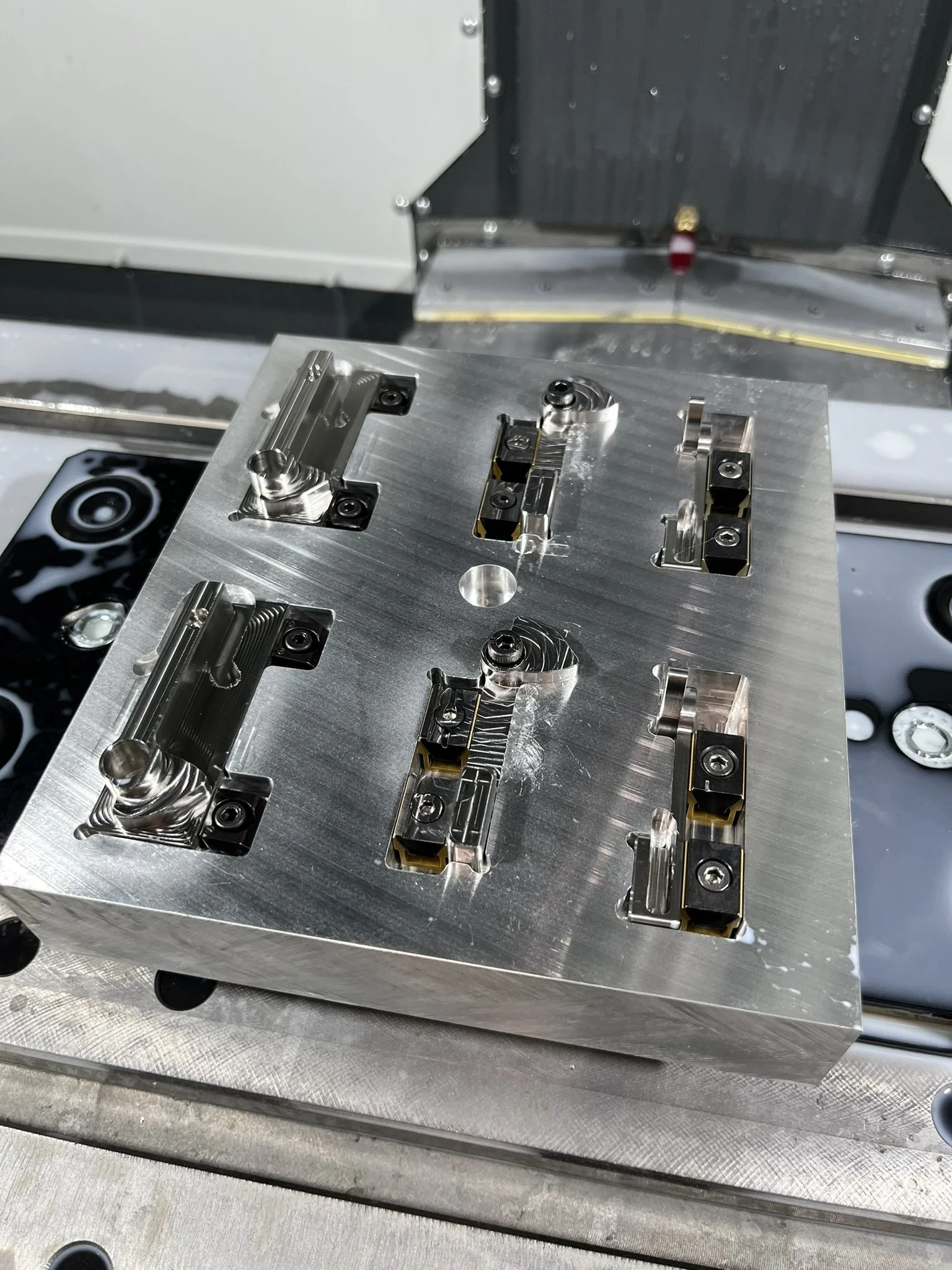

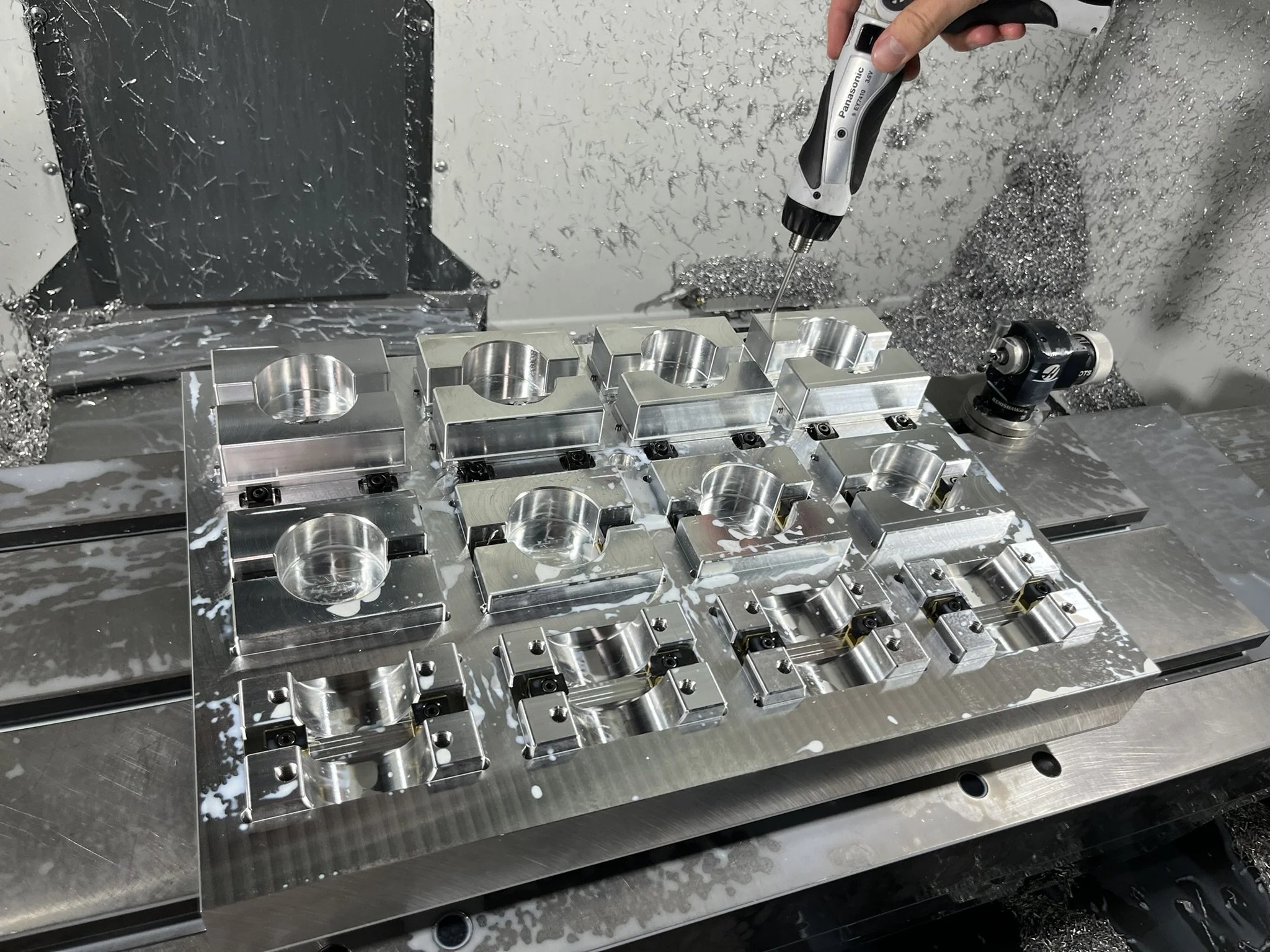

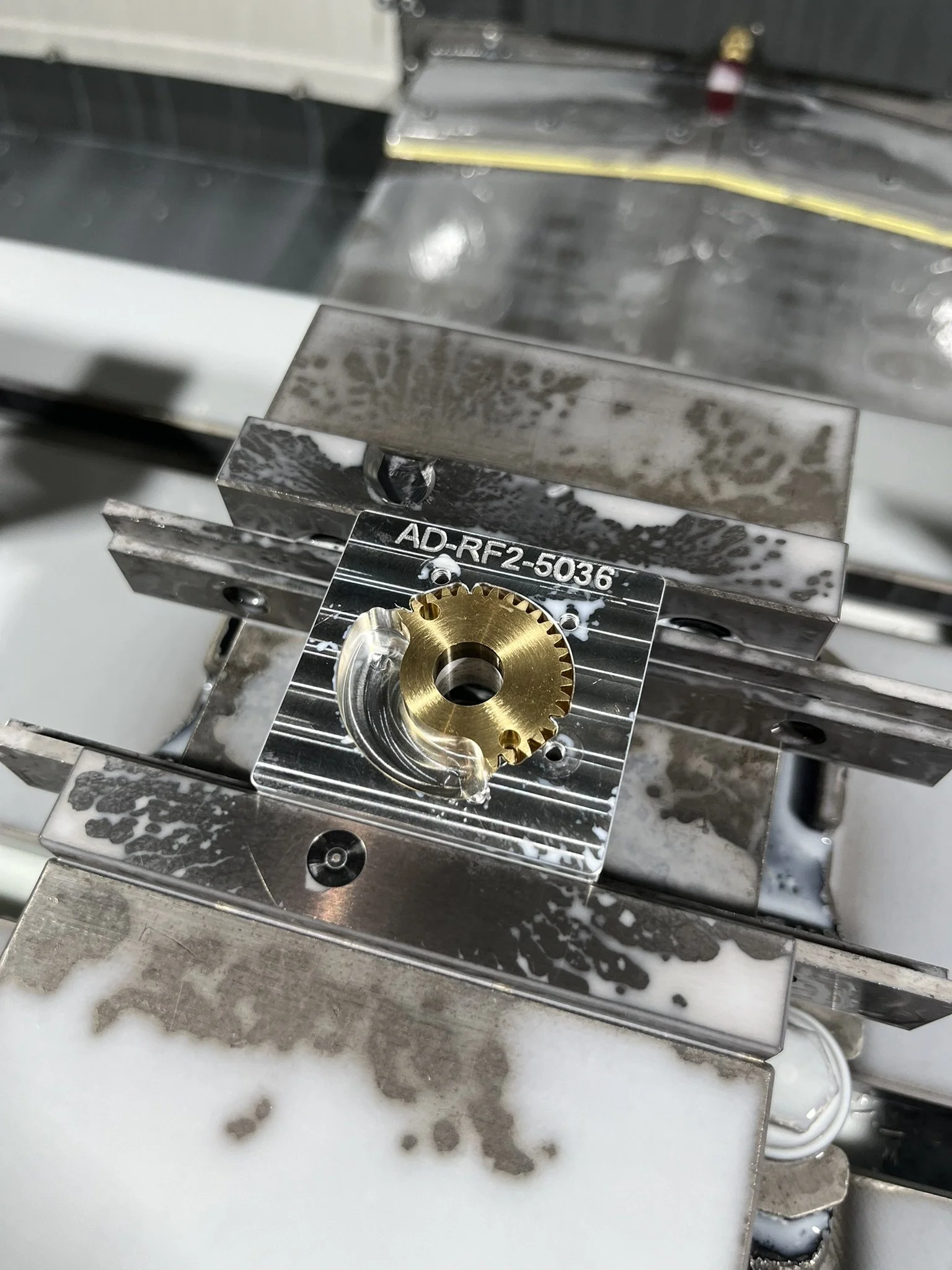

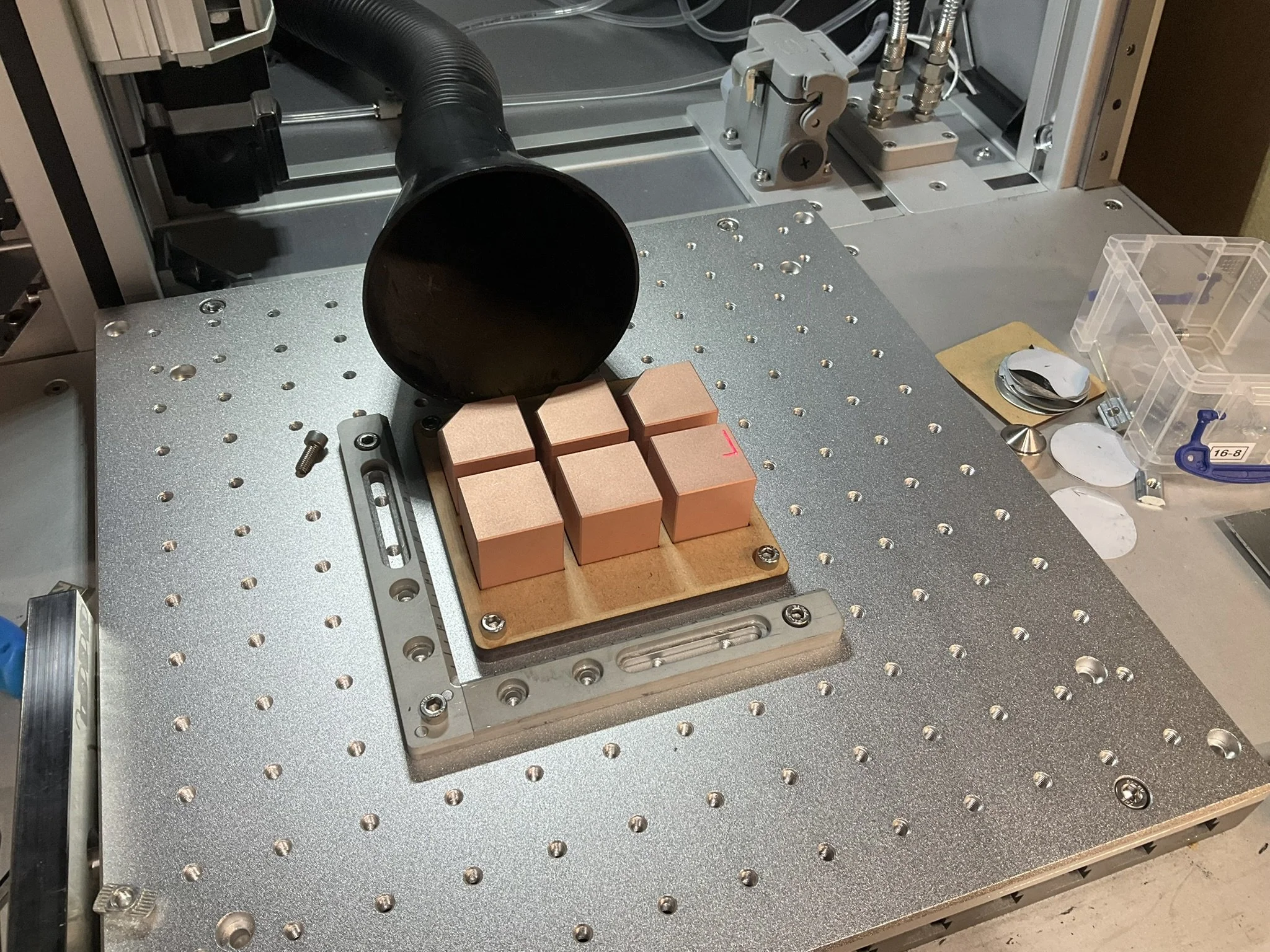

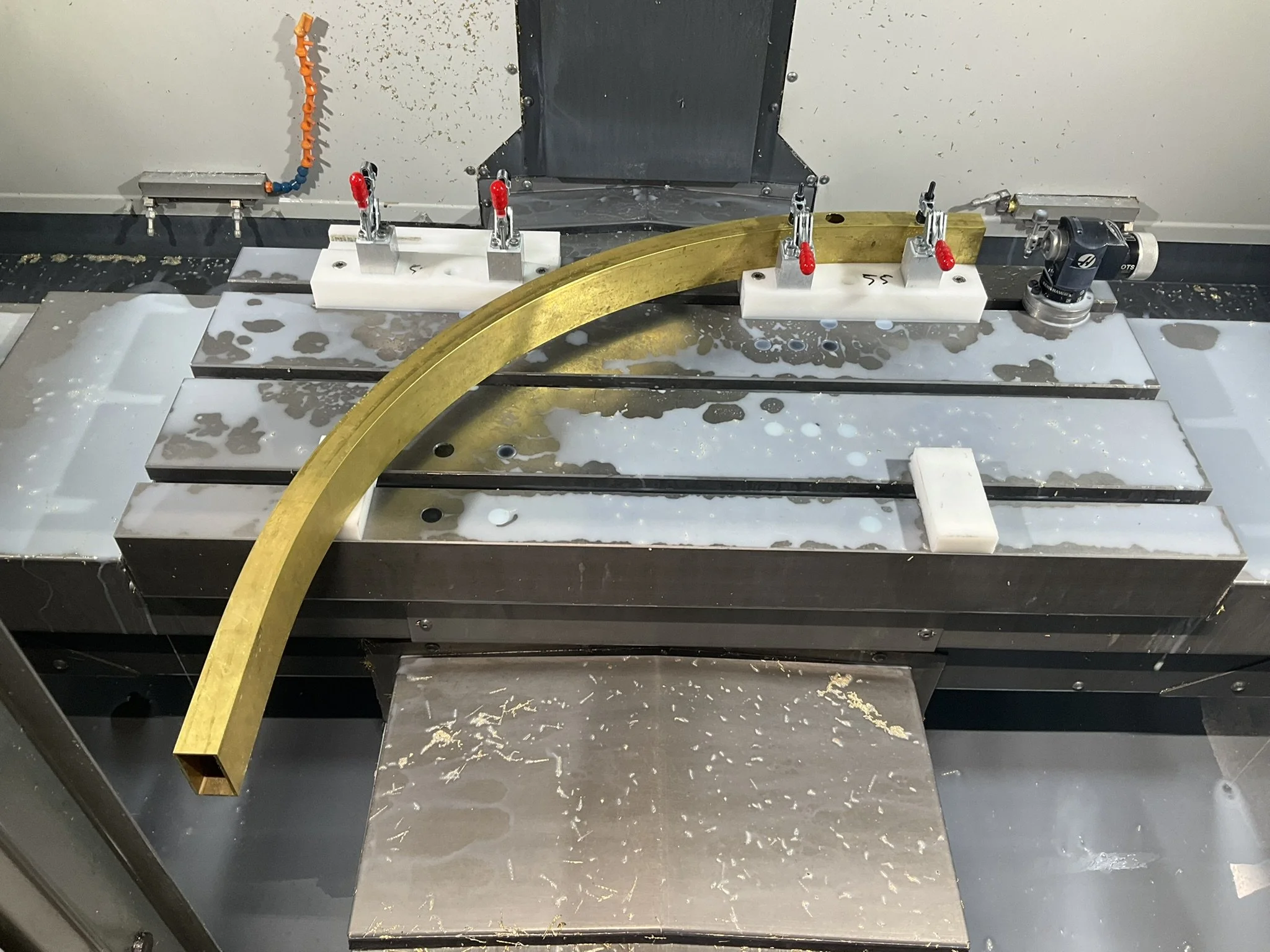

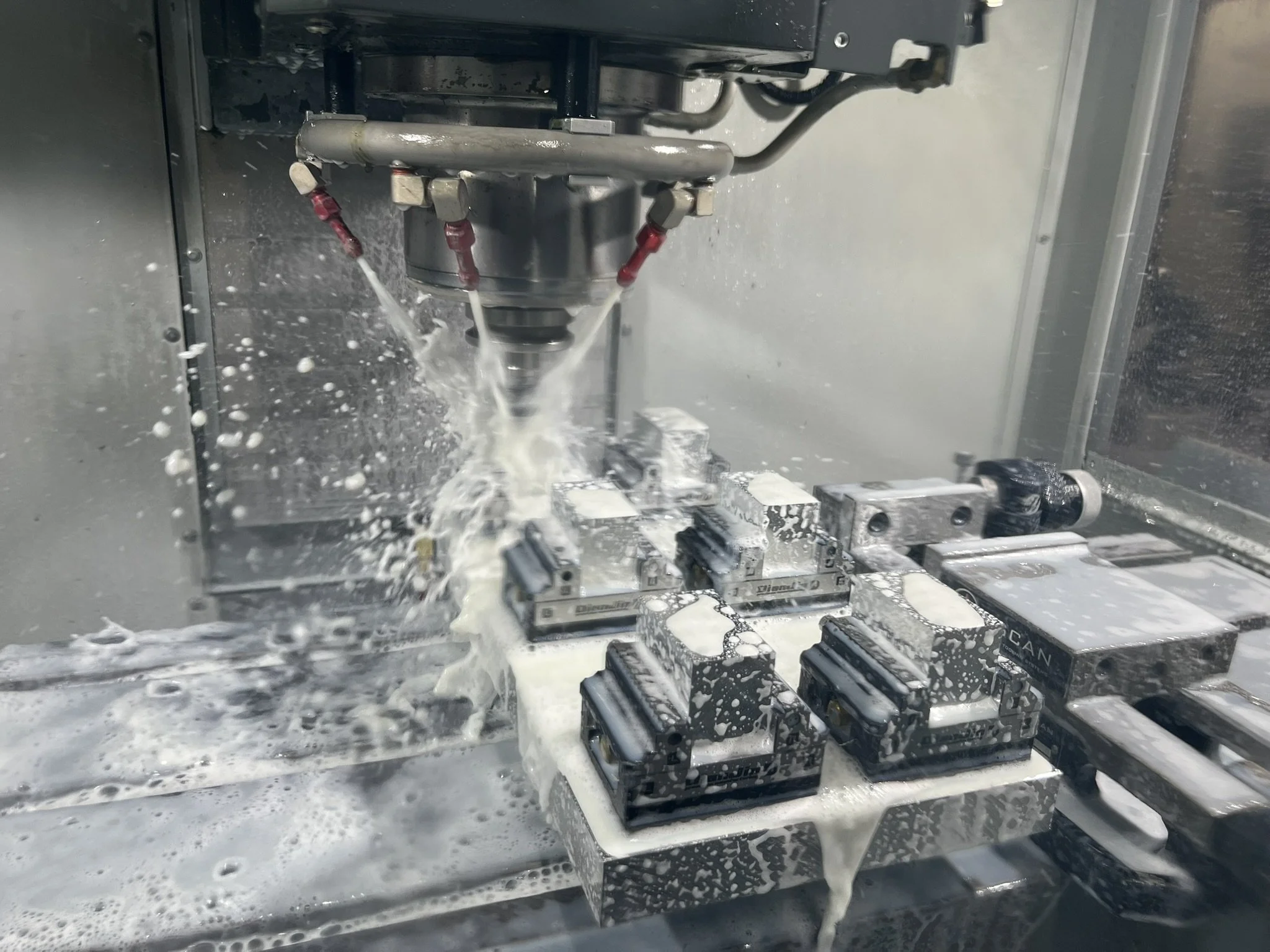

CUSTOM JIGS & FIXTURES

We design and make custom jigs and fixtures to accurately locate parts during machining. Depending on the application, these are either CNC machined or 3D printed. This allows us to support one off work through to repeat production, while maintaining consistency and accuracy.

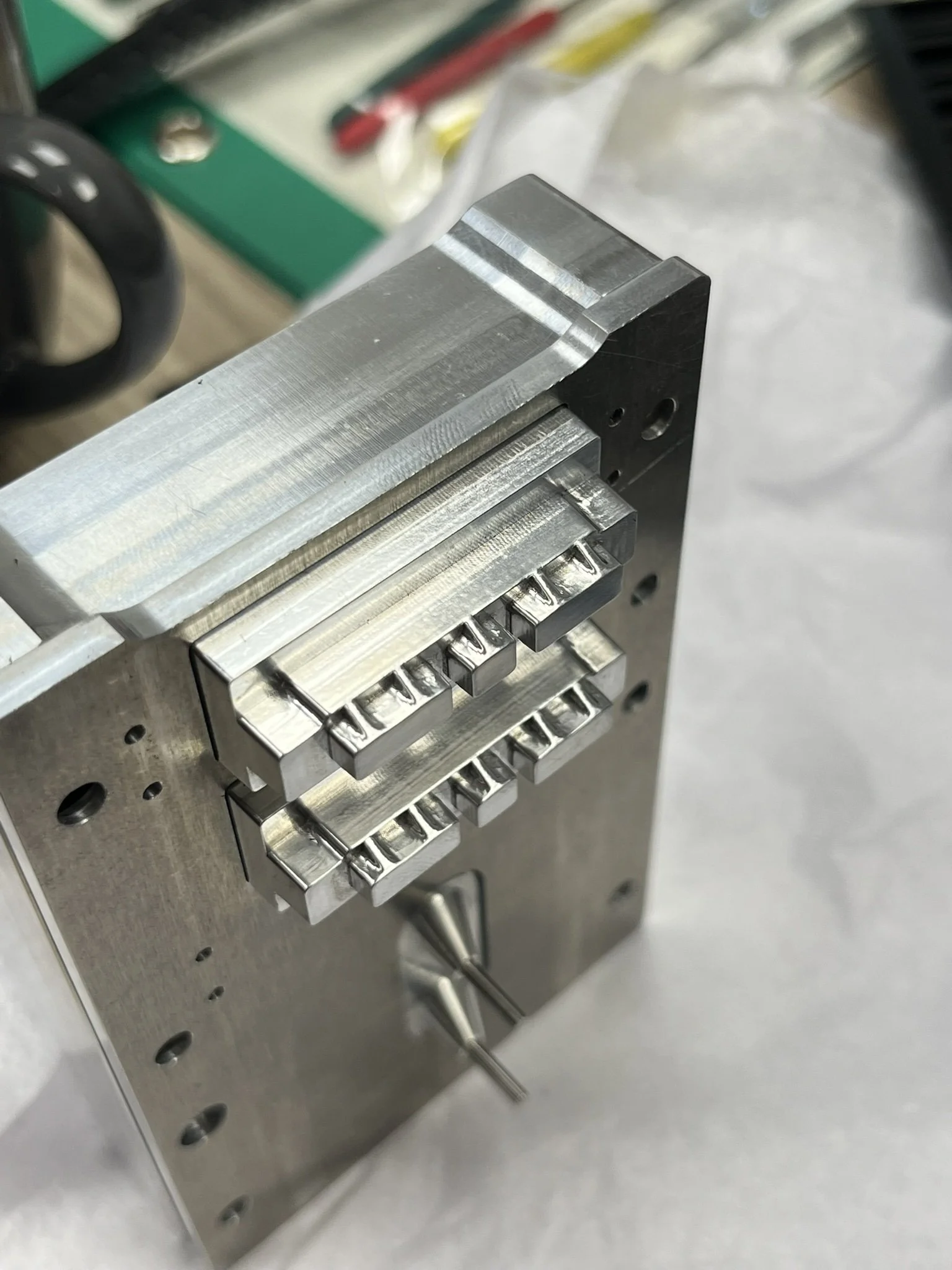

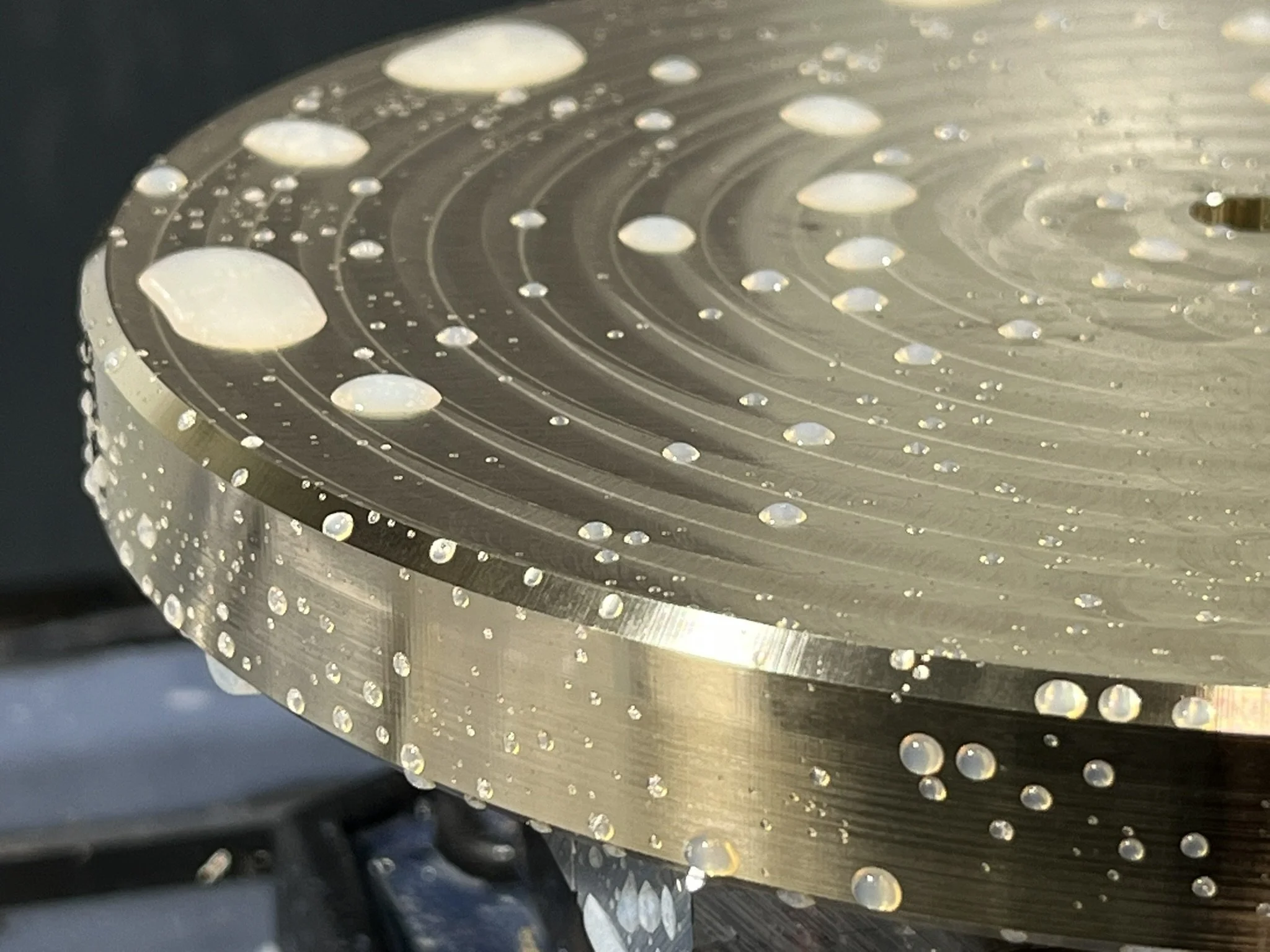

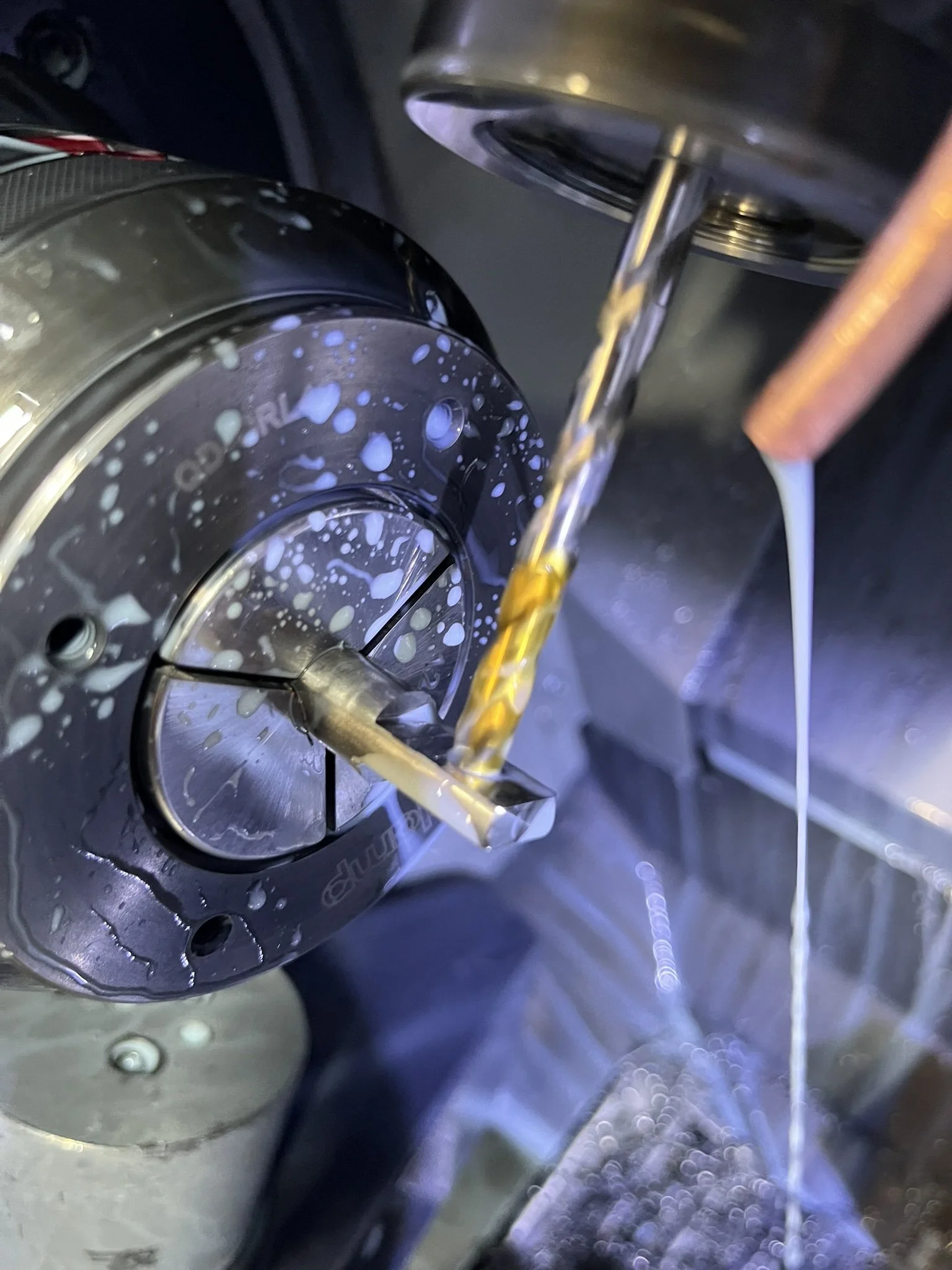

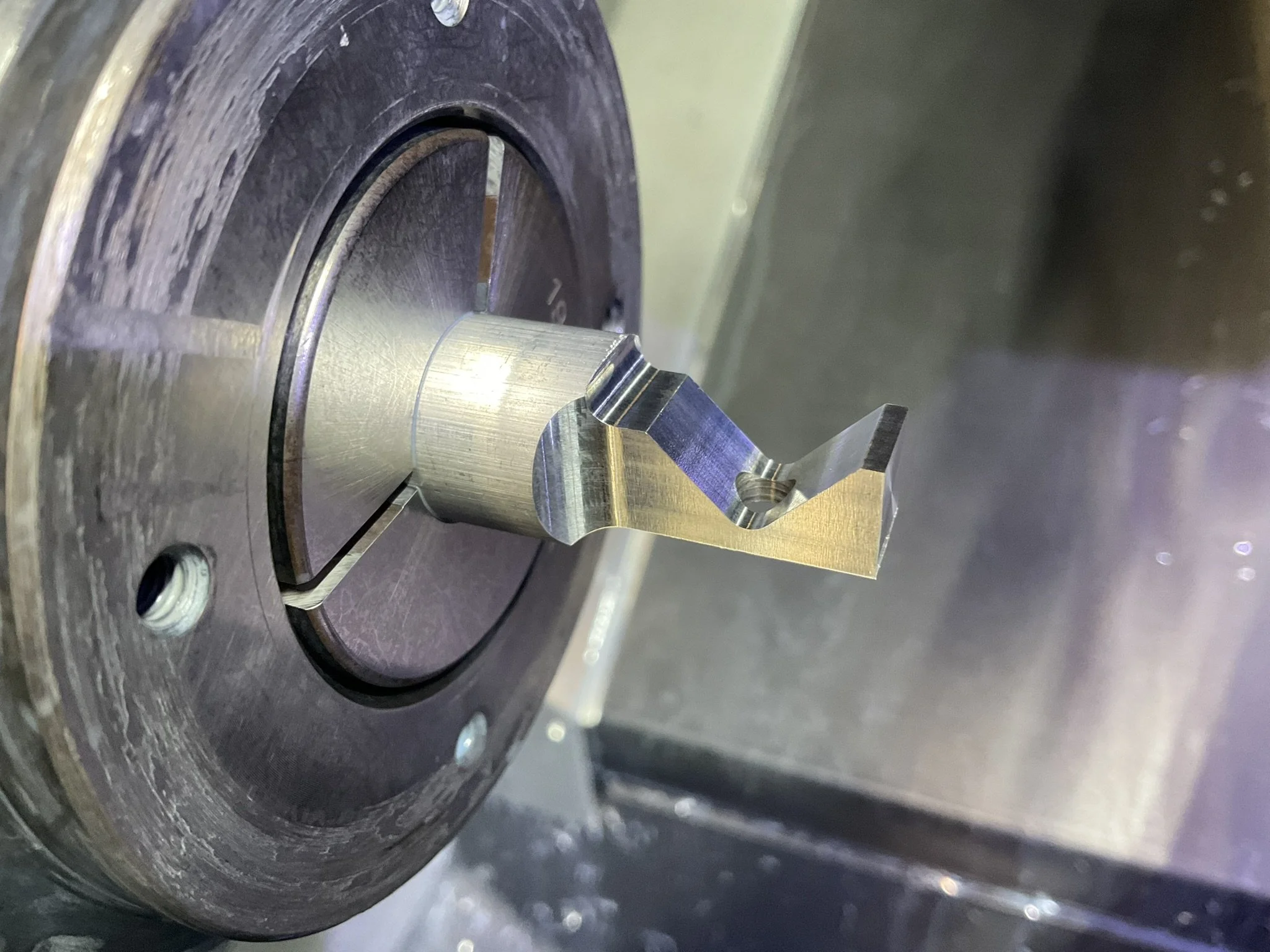

Y-AXIS TURNING CNC LATHE

Y-axis capability allows off centre features to be machined in a single setup, reducing handling and improving accuracy.

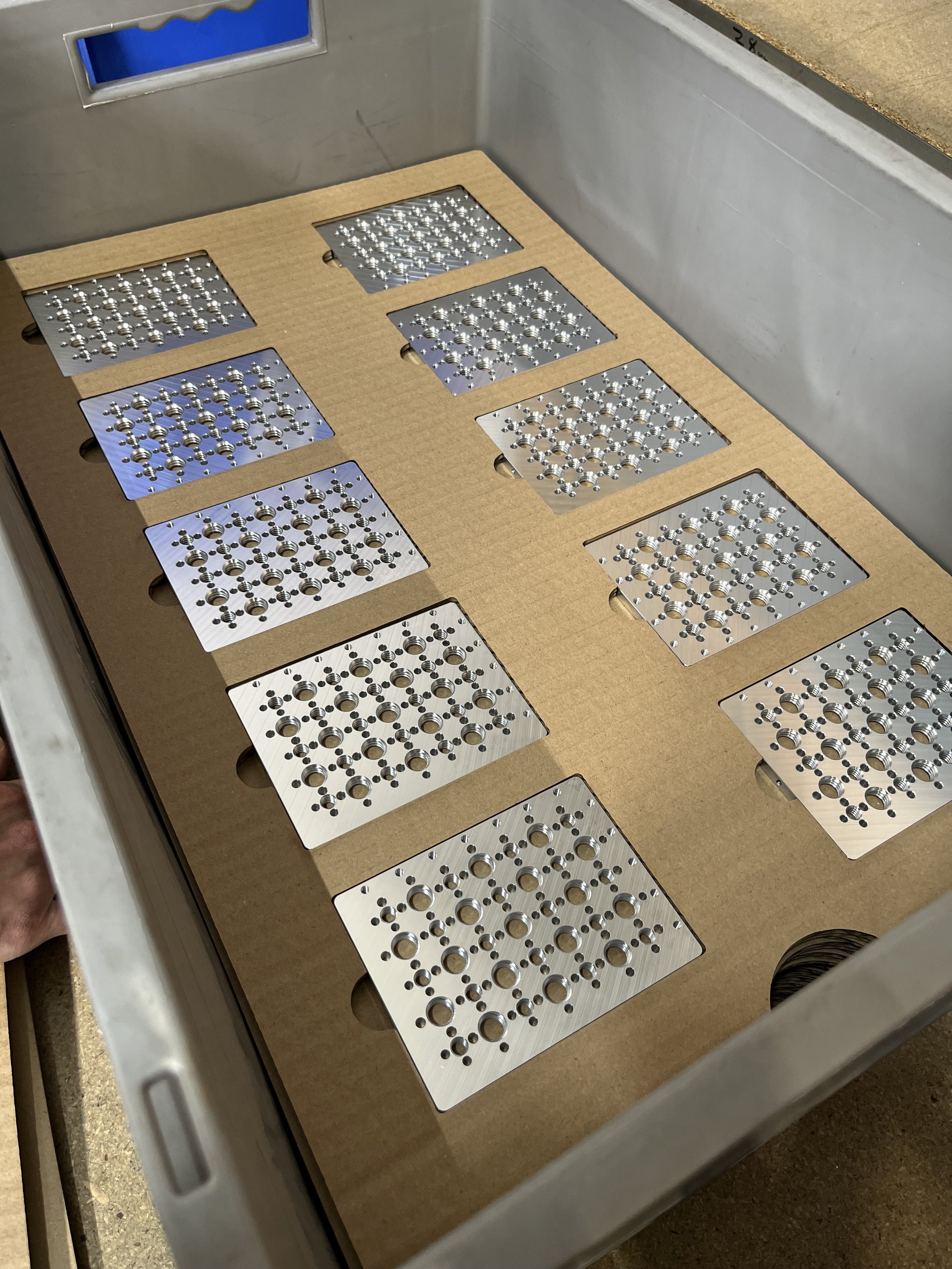

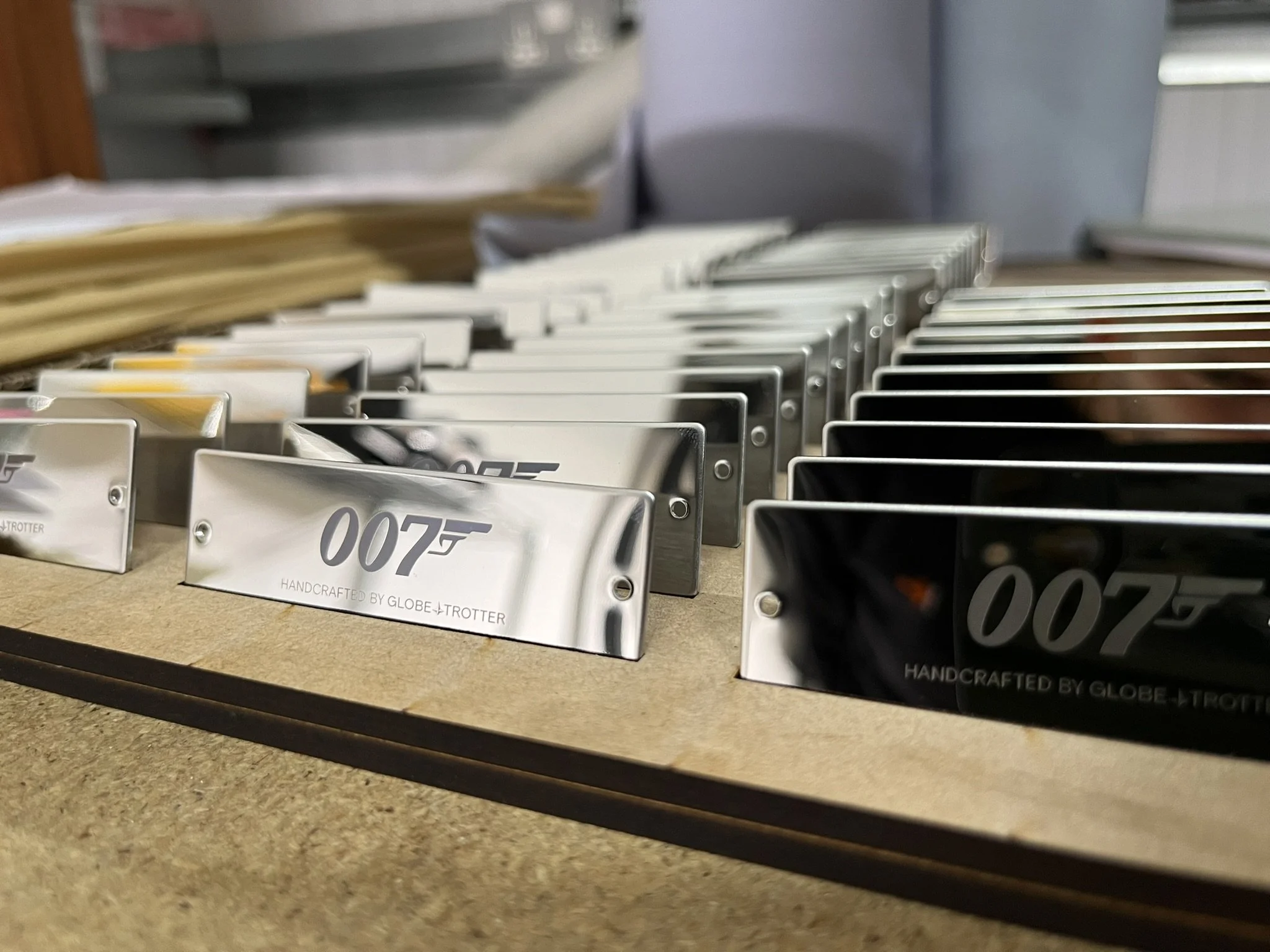

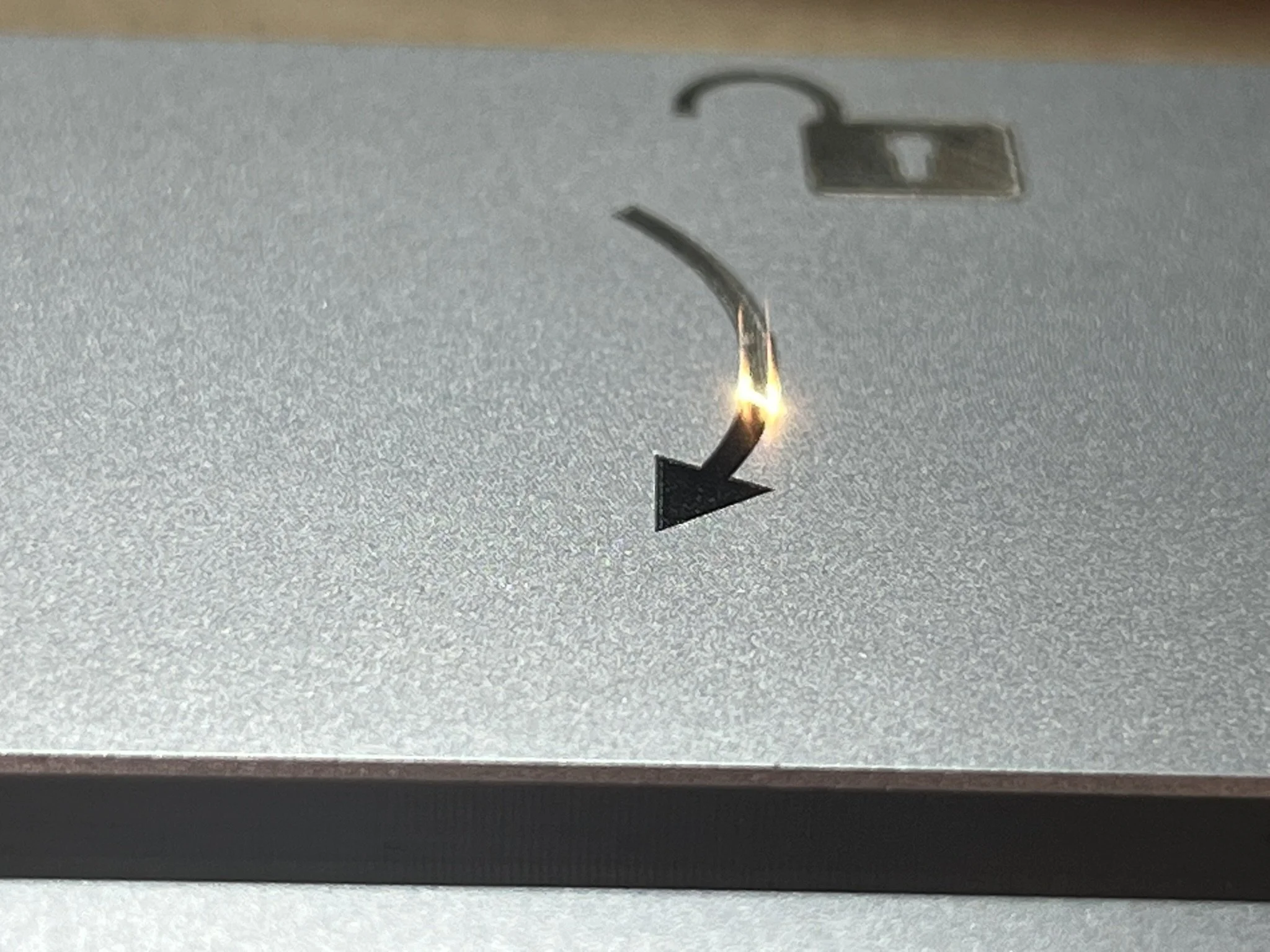

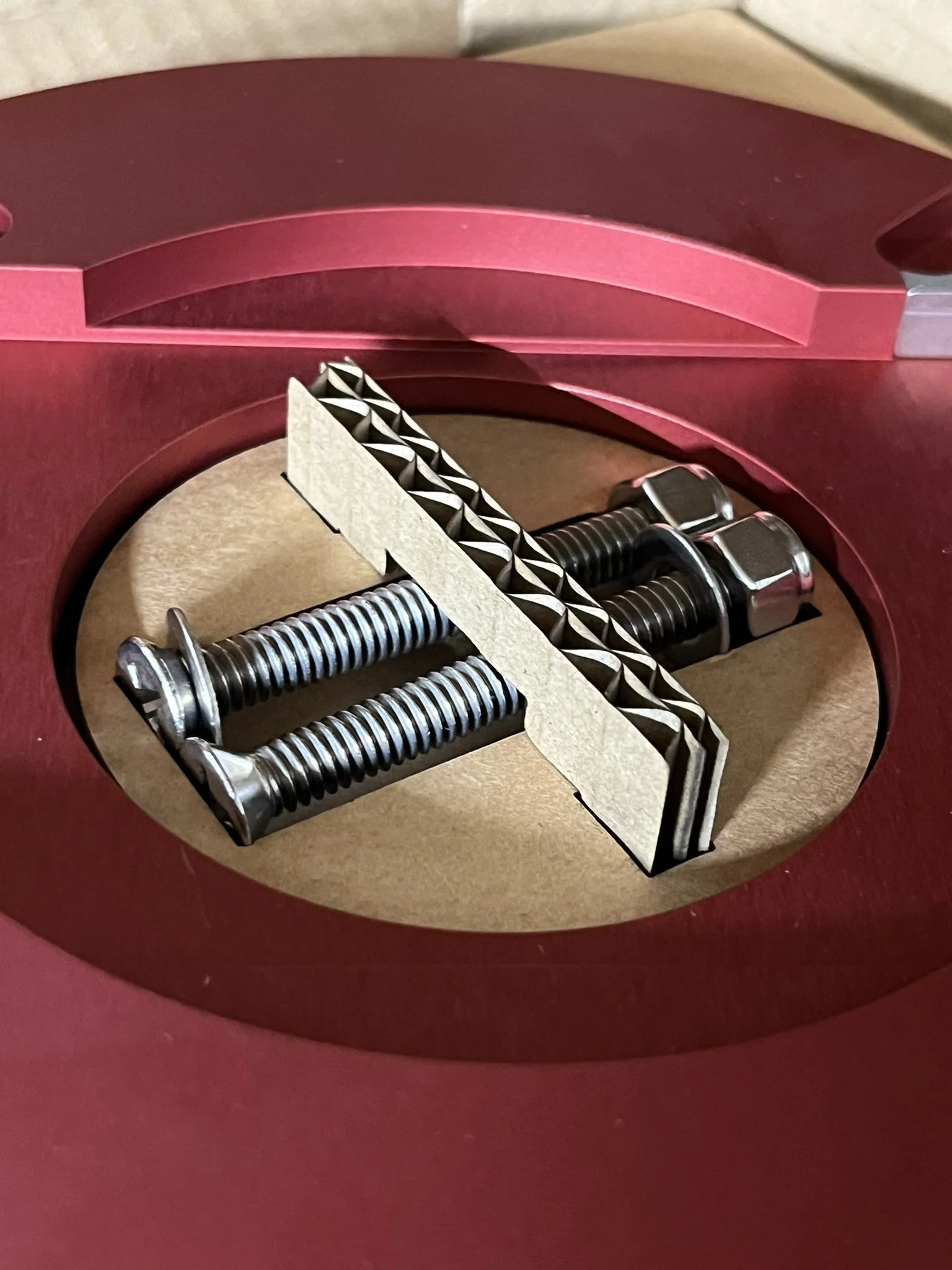

CUSTOM PACKAGING

For repeat jobs and larger quantity orders, we laser cut custom packaging in house to protect finished parts during transit and ensure consistent, repeatable packing for future orders.

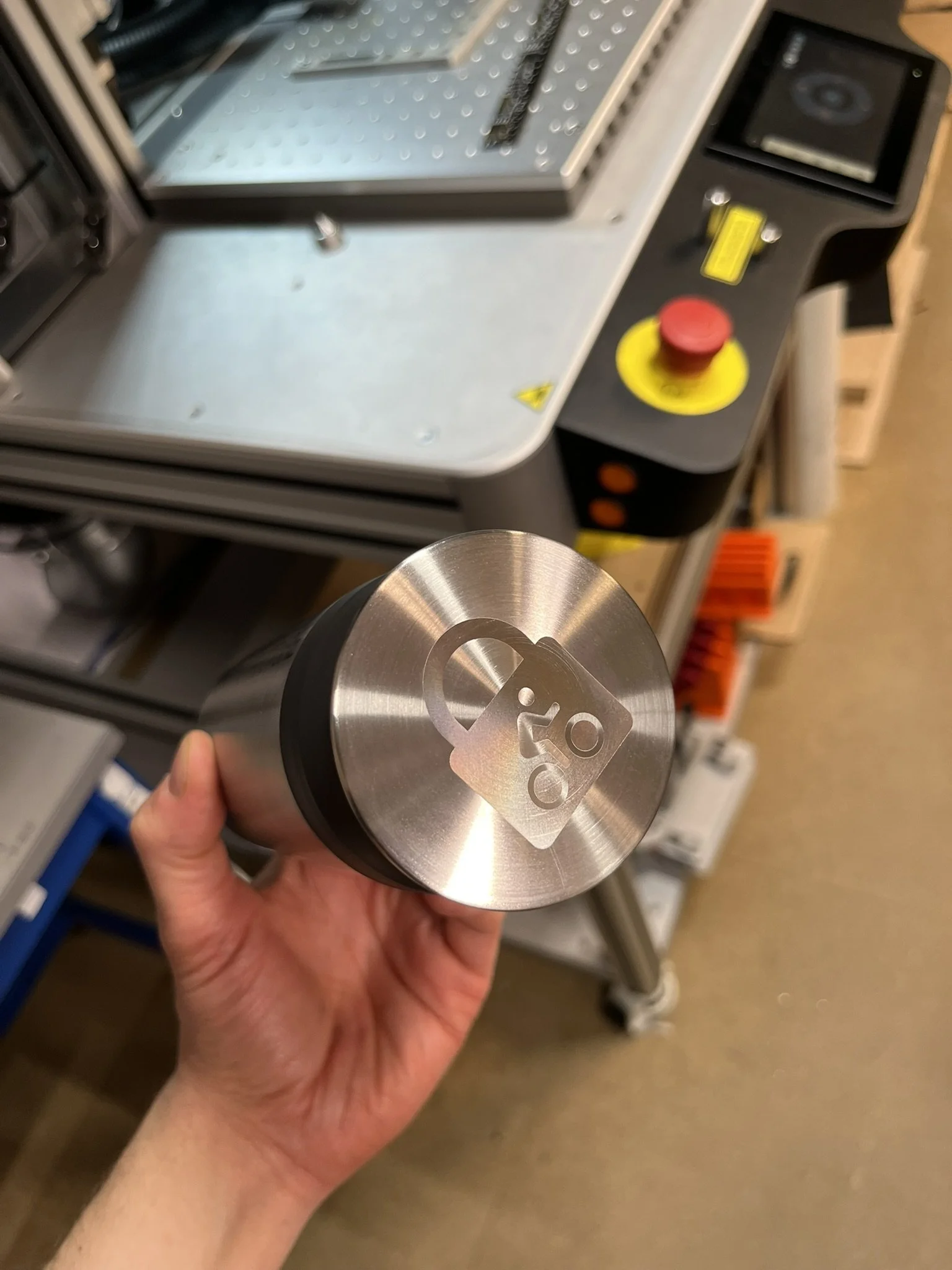

QC

Dimensional checks are built into our workflow to keep tolerances, fit, and repeatability consistent job to job.

OUR SERVICES

All of our processes are supported by in house CNC machining, marking, and prototyping.

In house milling for custom parts, prototypes, and repeat batches.

In house turning for accurate, reliable components.

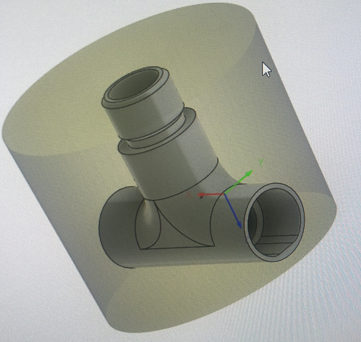

Support for preparing and validating parts for manufacture.

In house cutting and permanent marking for parts and assemblies.

WANT TO DISCUSS YOUR PARTS?

If you’re working on a new part or need help taking a design through machining, we’re always happy to take a look. Whether it’s a one off component or a repeat production run, we can advise on the best way to make it.