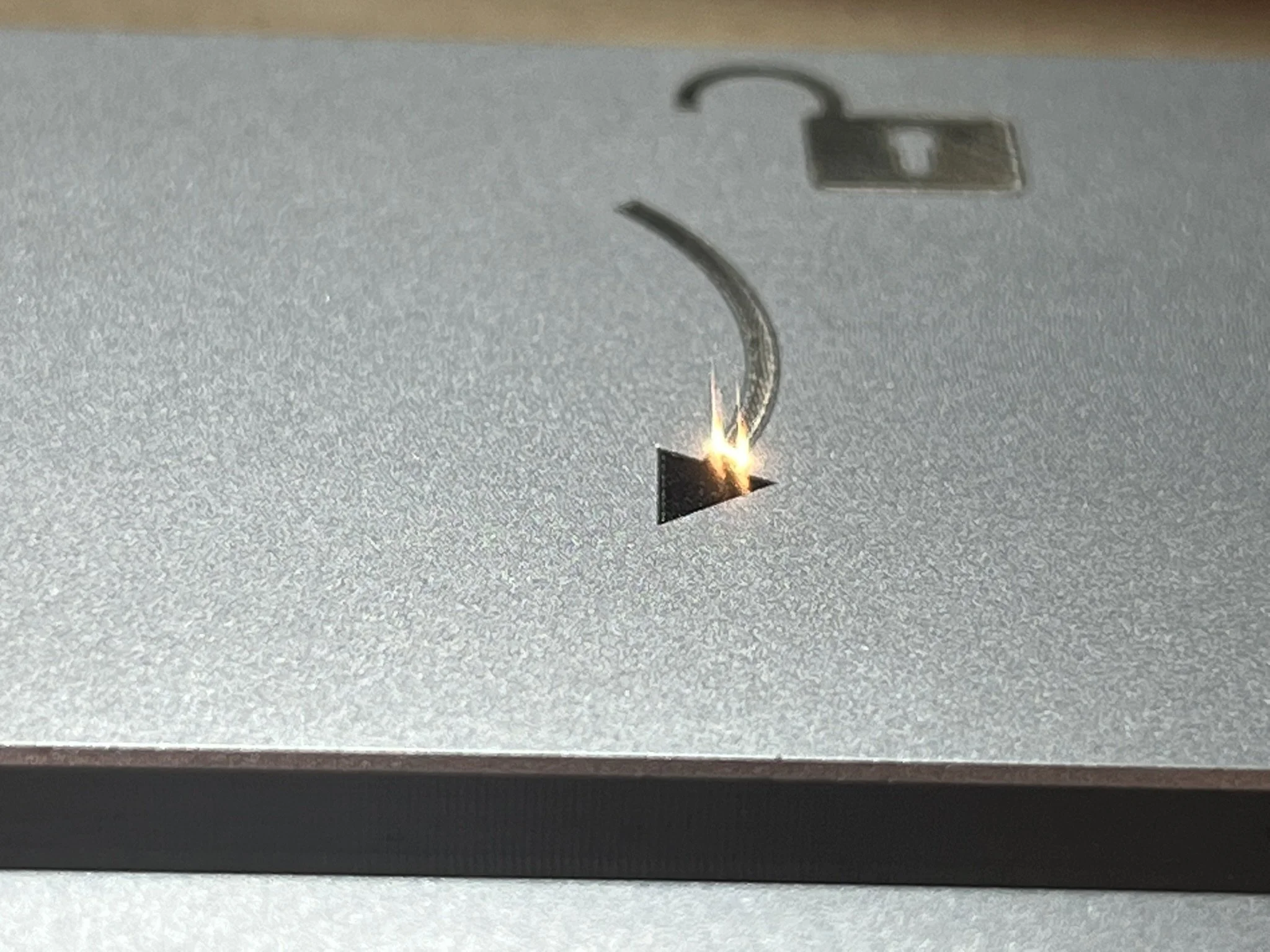

LASER CUTTING

FOR INSERTS, PANELS, GASKETS & PACKAGING LAYERS

WE CUT PARTS IN HOUSE FOR:

Packaging inserts & foam trays

Gaskets, seals & spacer layers

Panels, covers & housings for assemblies

Templates & jigs for laser marking & assembly

Diffusers & optical panels for lighting

Prototype, small batch & repeat batches

LASER CUTTING CAPABILITIES

We laser cut non metallic materials in house for prototypes, small batch and repeat batches, often alongside CNC machined parts for assemblies and packaging.

MATERIALS

Acrylic (clear, coloured & opal), plywood, MDF, card, EVA foams, LD foams, gasket materials, leather and selected plastics. Suitable for inserts, trays, diffusers, gaskets, templates and assembly components.

THICKNESSES

Acrylic up to ~12mm

MDF up to ~10mm

Plywood up to ~5mm

Foams up to ~25mm

Gaskets & rubber up to ~5mm

Leather typically up to ~3–4mm

PARTS WE COMMONLY CUT

Inserts & trays for batch packaging

Gaskets, seals & spacer layers

Diffusers & optical panels for lighting assemblies

Panels, covers & housings

Templates & jigs for assembly and laser marking

Custom foam for assemblies & shipping

Product development prototypes

INDUSTRIES WE SUPPORT

Lighting & optical

Hardware & product development

Robotics & instrumentation

OEM & manufacturing

Assembly & packaging for repeat supply

WHAT TO SEND

DRAWING OR CAD

DXF preferred. PDF drawings accepted for quoting. STEP files fine if earlier in development.

QUANTITIES

Prototype, small batch or repeat batches.

MATERIAL

Acrylic, plywood, MDF, foam, gasket, leather or card.

Include thickness if known.

NOTES

Cut/engrave details, fit/assembly info, or packaging requirements.

If you’re earlier in the design process, send what you have and we’ll review.

LASER CUTTING FAQS

-

Yes, we cut opal and coloured acrylic for diffusers and optical panels used in lighting assemblies.

-

Yes, we cut EVA and LD foams for trays, inserts and batch packaging.

-

Yes , we cut templates and jigs in house for positioning parts during laser marking and assembly. Useful for repeat batches and consistent placement.

-

Laser cutting is well suited for inserts, diffusers and jigs where consistent fit is important. Tolerance depends on material and thickness; tell us if you have a fit requirement.

-

Yes, we support prototyping and small batch work for hardware and product assemblies. Repeat batches supported for OEMs.

-

DXF preferred. PDF drawings fine for dimensions. STEP files accepted if earlier in development.

MORE UNDER ONE ROOF

Based in Hertfordshire, we support hardware teams, OEMs and manufacturers with laser cutting, CNC milling, CNC turning, laser marking and prototyping, small batch and repeat production across the UK.

For housings, covers and inserts used in hardware assemblies and lighting products.

For fittings, threaded features and components behind panels and enclosures.

For part numbers, QR codes, branding and traceability, often paired with jigs for batch work.

For early concepts, iteration and testing before moving into batch production.

READY TO GET PARTS CUT OR MACHINED?

Send us your drawing or CAD file, we’ll review it, ask any technical questions, and come back with next steps.