CUSTOM LIGHTING

CNC MACHINED HOUSINGS, HEATSINKS & LED INTEGRATION FOR ARCHITECTURAL, HORTICULTURAL & COMMERCIAL LIGHTING

We manufacture custom lighting components and hardware, including CNC machined housings, heatsinks and carriers with optional LED hardware integration.

Supporting architectural, horticultural and commercial lighting projects across the UK, from prototypes and pre-production builds through to batch supply.

LIGHTING CAPABILITIES

We manufacture lighting components, housings and assemblies with LED integration for architectural, horticultural and commercial projects. Suitable for prototypes, small batch and repeat production.

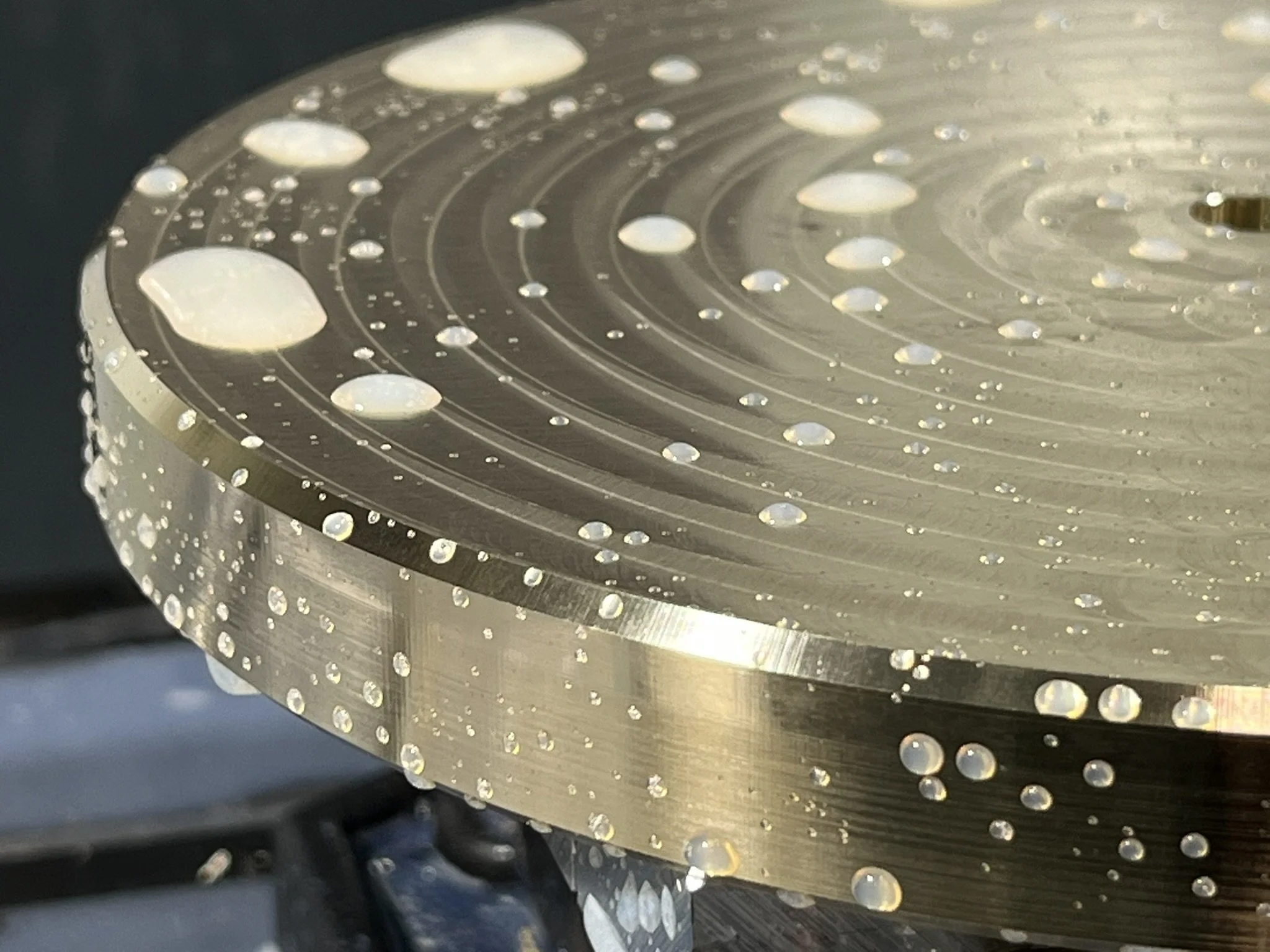

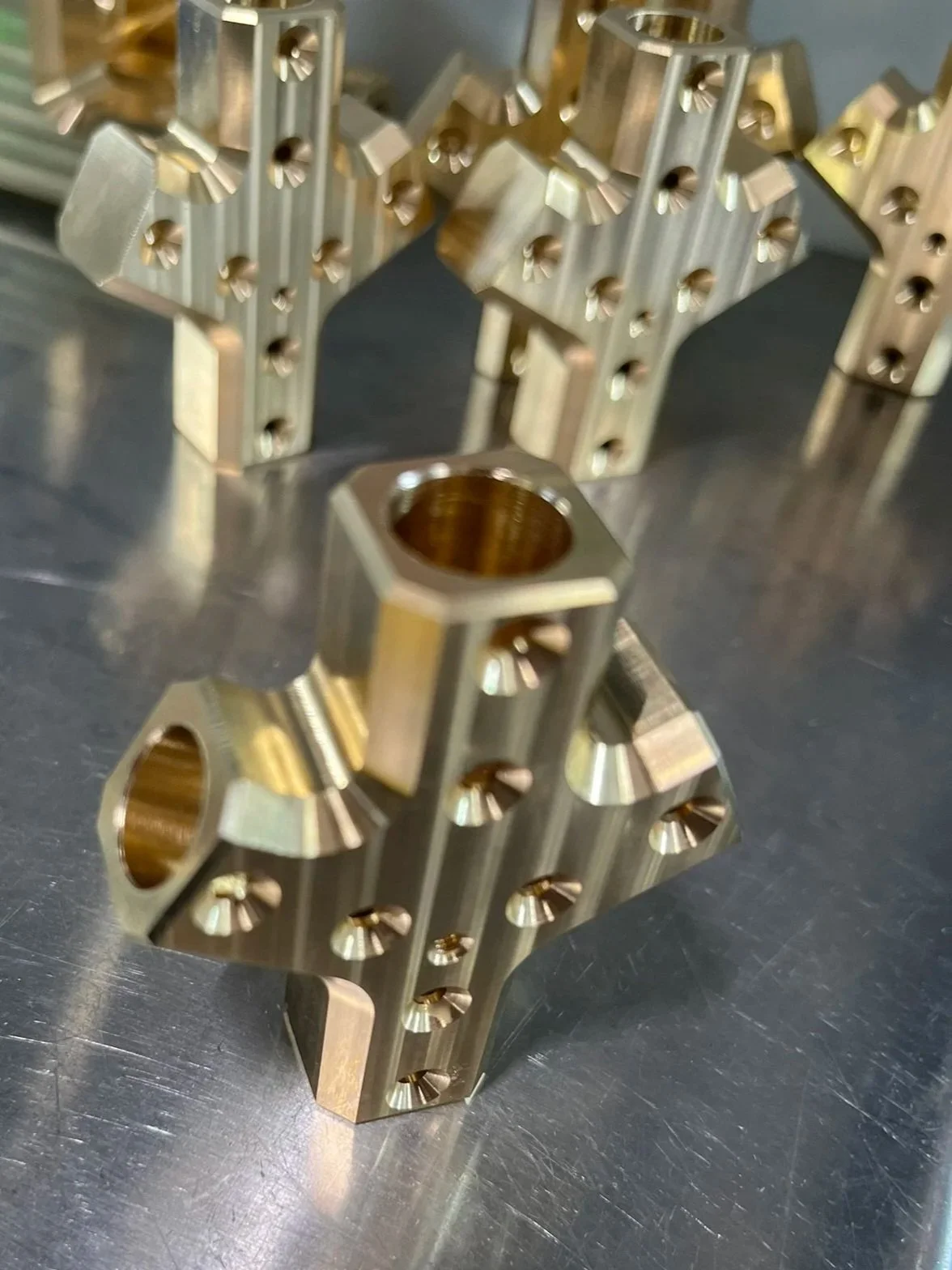

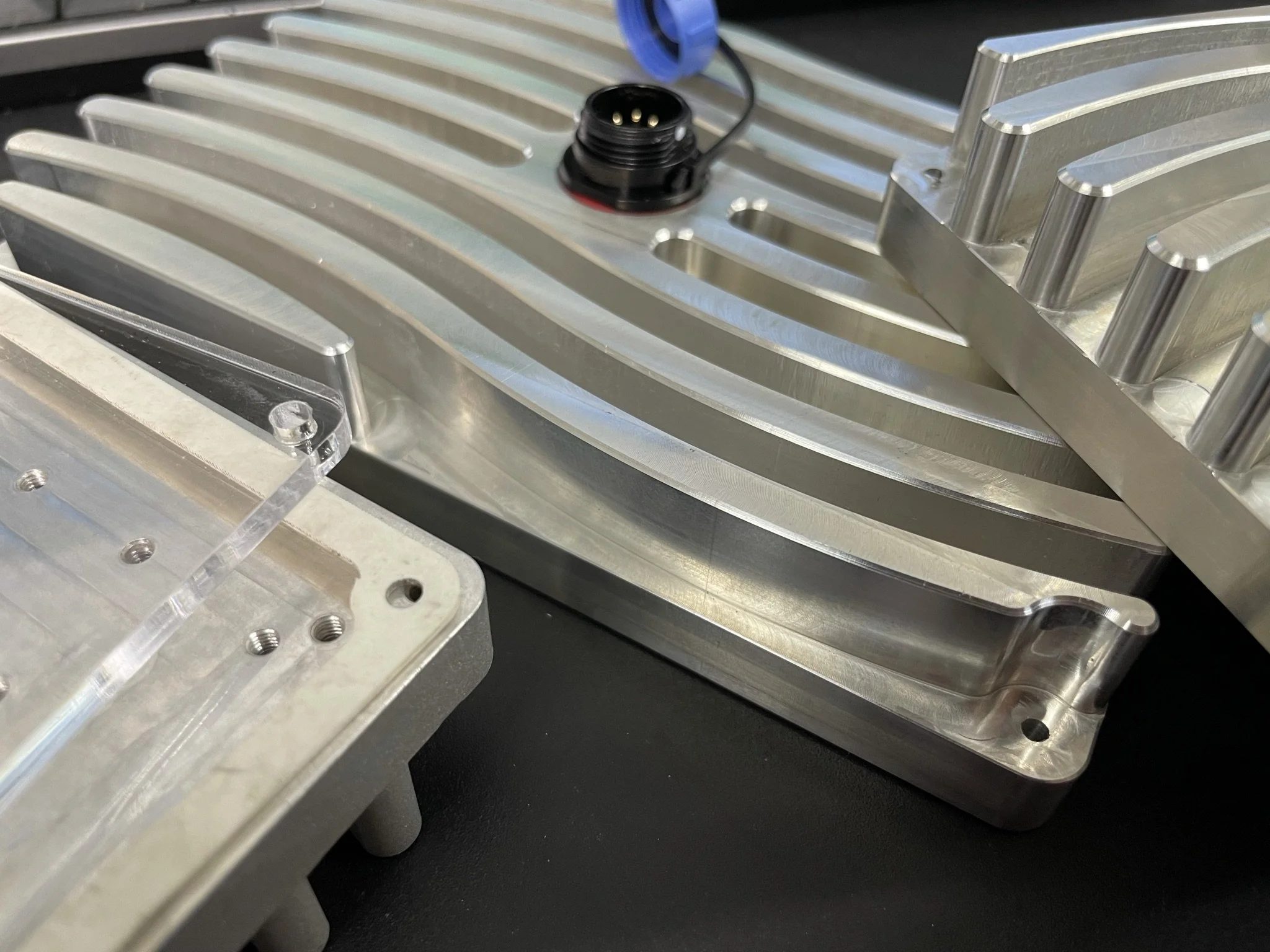

CNC MACHINED COMPONENTS

Housings, bezels, heatsinks and mounting features machined in brass, aluminium and plastics for architectural and horticultural assemblies.

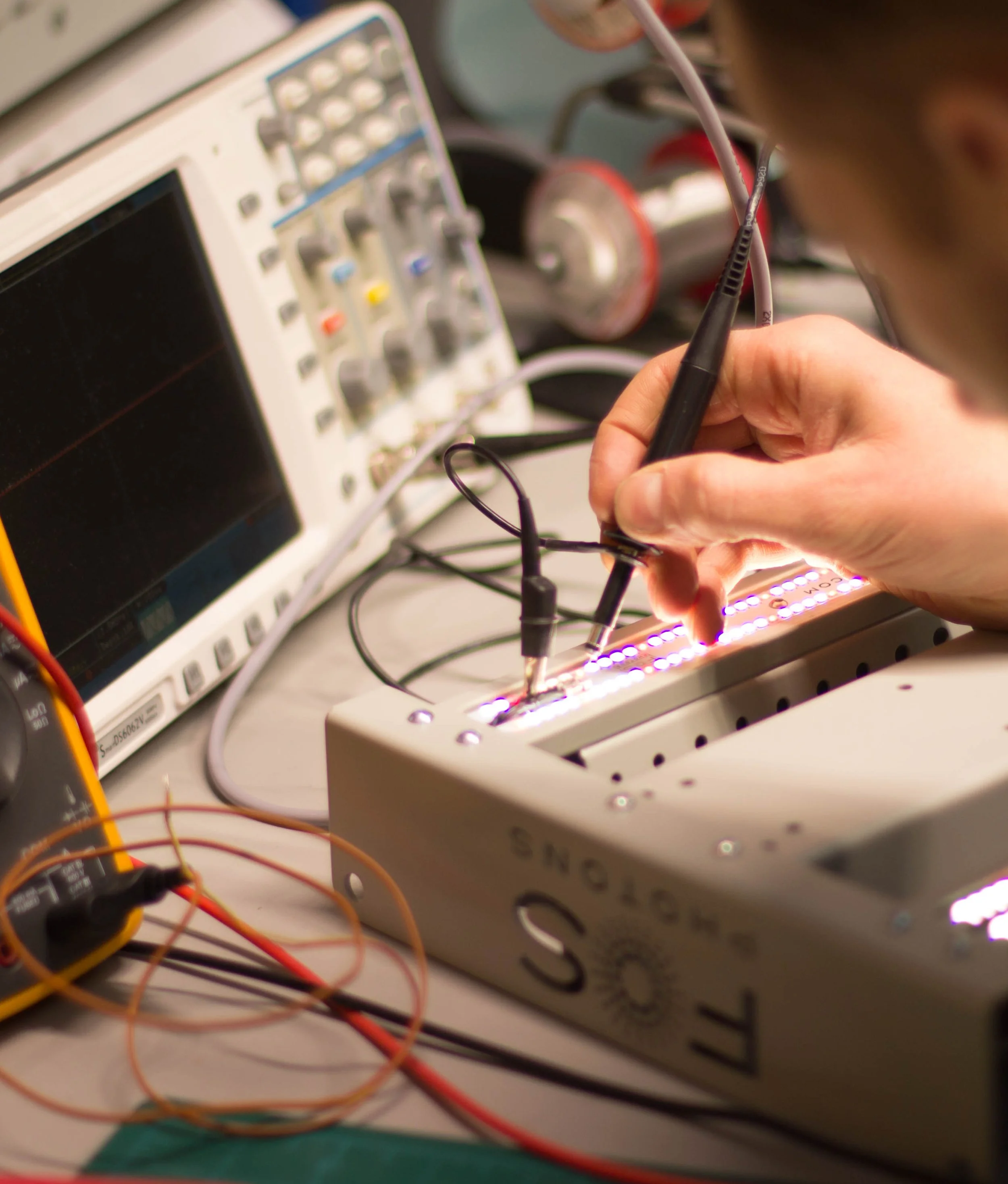

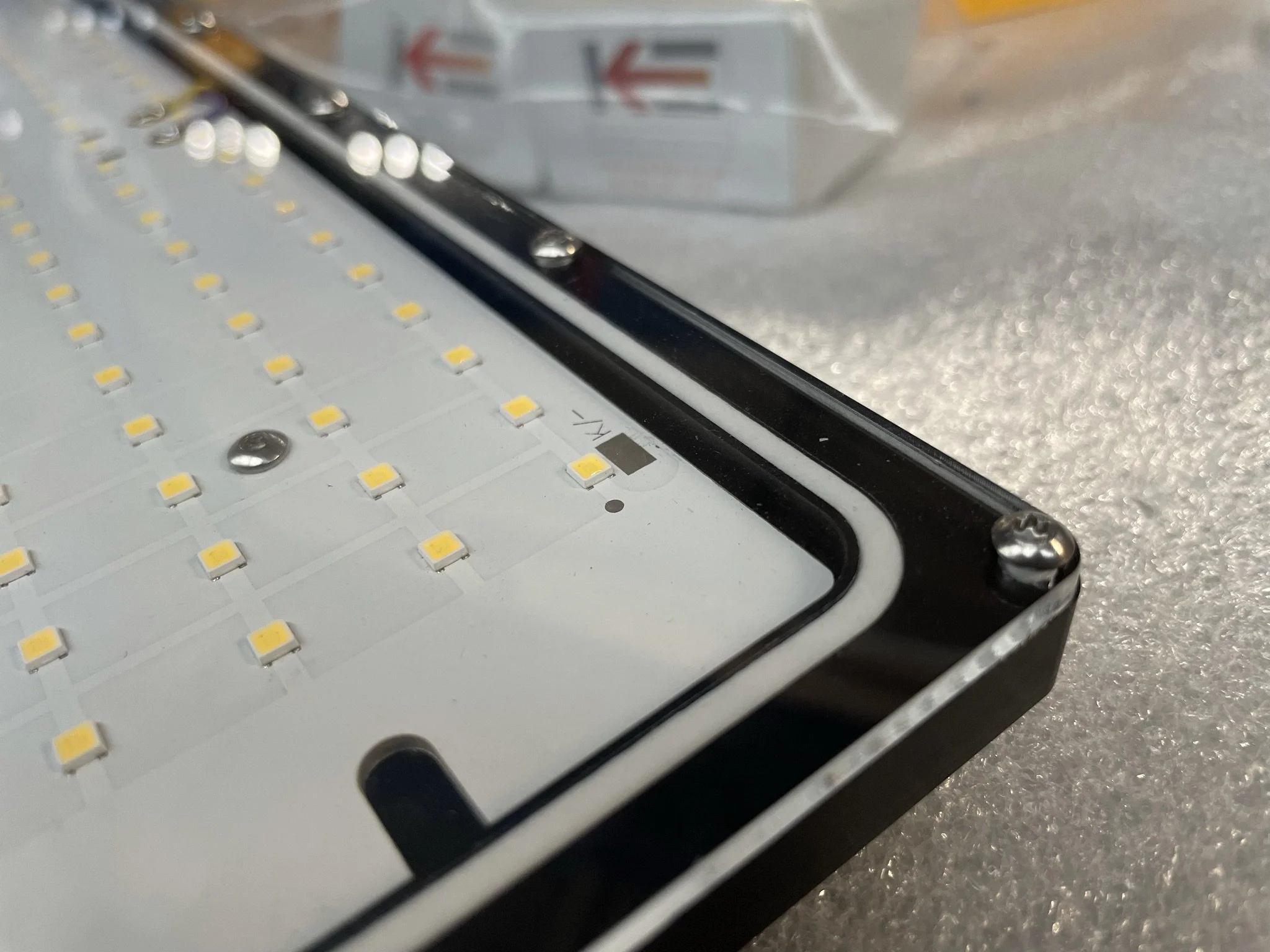

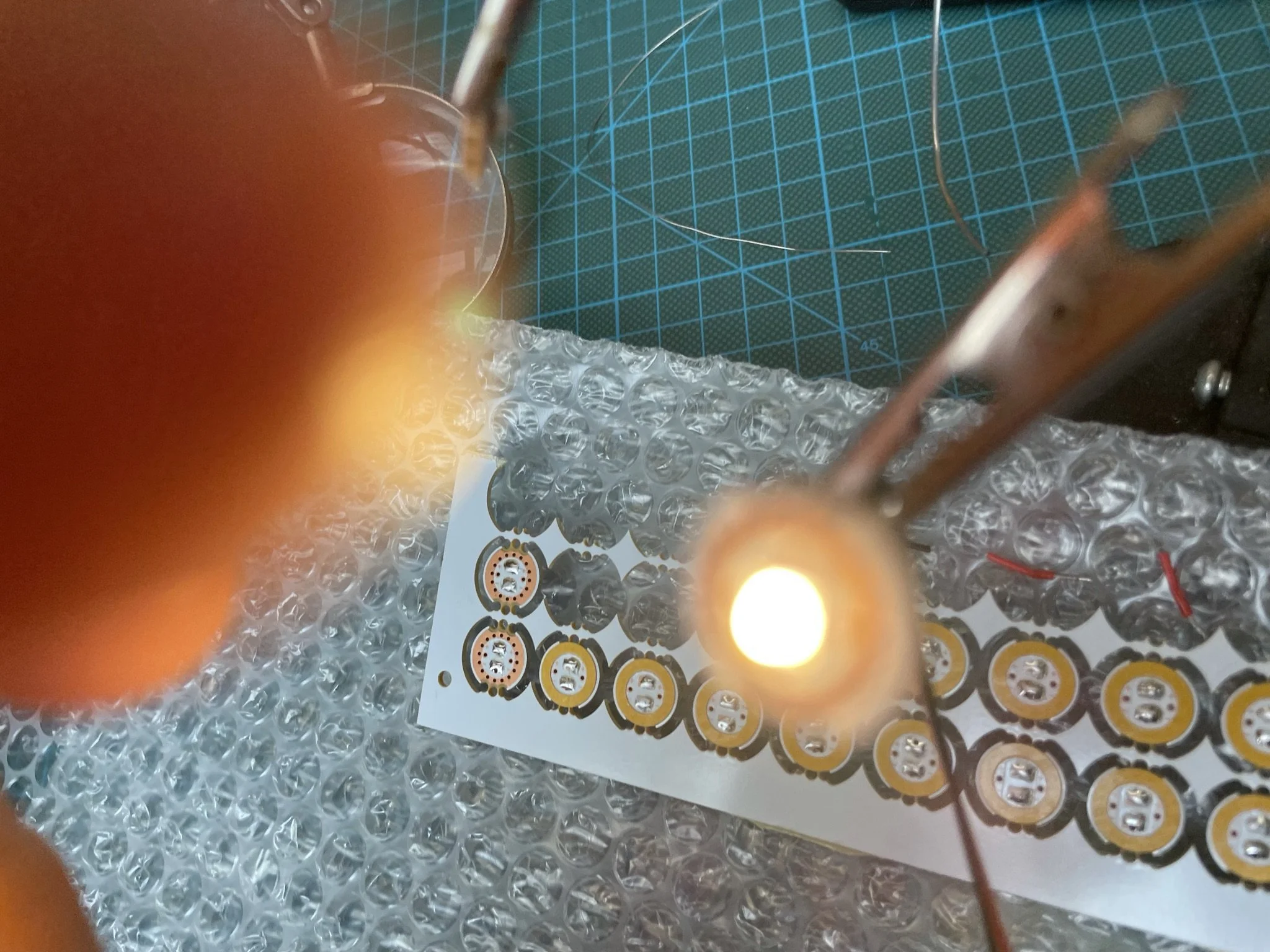

LED INTEGRATION & HARDWARE

Carriers, mounting hardware, thermal interfaces LED integration for machined housings and heatsinks. Assembly available when parts are made in house.

PROTOTYPING & DEVELOPMENT

Support for concept builds, early iterations and testing before moving into production runs.

BATCH PRODUCTION

Suitable for prototype, small batch and production quantities. Consistent machining and finishing for OEM lighting products.

INDUSTRIES & PRODUCT TYPES

We support engineered lighting projects that require CNC machined housings, heatsinks and lighting hardware. Components only machining is welcome, with optional LED hardware integration for prototypes and batch production.

HORTICULTURAL/GROW

LIGHTING

LED grow lighting components including machined heatsinks, housings and carriers for prototype and batch production.

ARCHITECTURAL & INTERIOR

Machined housings, bezels and lighting hardware for architectural and interior lighting projects, where form, finish and mounting detail matter.

COMMERCIAL INDOOR & OUTDOOR LIGHTING

Lighting hardware, fixtures and housings for commercial indoor and outdoor applications, including retail, signage, hospitality and display installations.

CUSTOM LIGHTING FAQS

-

We commonly machine housings, heatsinks, carriers, bezels, diffusers, optical panels, brackets, LED trays and other lighting hardware for architectural, horticultural and commercial projects.

-

Yes, we manufacture prototypes, pre-production builds and batch quantities for lighting OEMs, designers and commercial projects.

-

Yes, we can integrate around customer-supplied LED boards, optics and drivers for prototype and batch builds. We do not design PCBs or electronics.

-

We can supply LED boards, drivers and optics when required, or integrate customer-supplied components. PCB and electronic design is typically handled by the lighting OEM or designer.

-

We focus on engineered lighting hardware rather than decorative or consumer lighting. Bespoke projects are possible when CNC machined components are involved.

-

Yes, CNC milling and turning are carried out in house for lighting housings, heatsinks and hardware. LED hardware integration and light assembly support is available when we manufacture the components.

-

Finishing can be arranged on request, although many lighting customers prefer to use their own approved suppliers for colour and surface specifications.

-

We regularly machine aluminium, brass and engineering plastics for lighting components, with stainless steel used where required.

WHAT TO SEND

DRAWINGS OR CAD FILES (STEP, DXF or PDF)

QUANTITIES

(prototype, pre-production or batch)

MATERIALS

(aluminium, brass or plastics)

NOTES

(LED hardware, optics, mounting or finishing)

If you’re earlier in the design process, feel free to send what you have, we’re happy to review.

MORE UNDER ONE ROOF

Based in Hertfordshire, we provide CNC turning, CNC milling, laser cutting, laser marking and finishing support for prototype, small batch and repeat production across the UK.

Turned features for bezels, collars, threaded components and mounting hardware.

Aluminium, brass and engineering plastics machined for lighting housings, heatsinks and hardware.

Rapid machining and sample builds for concept evaluation, testing and pre production runs.

Diffusers, optical panels and custom packaging cut in acrylic and engineering plastics, with optional batch marking for branding and traceability.

READY TO GET PARTS MADE?

Send us your drawing or CAD file and we’ll review it, ask any questions, and come back to you with next steps.