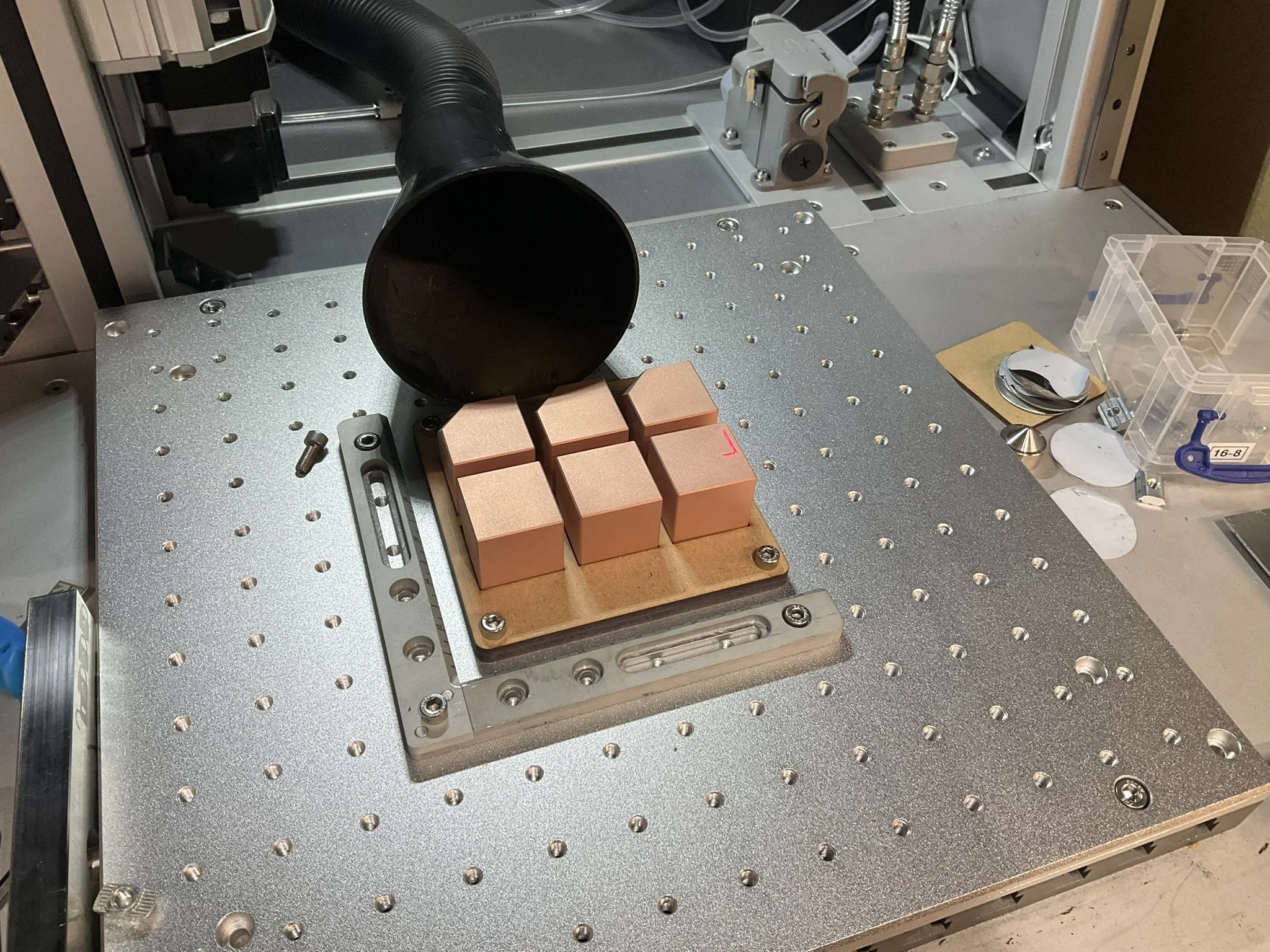

LASER MARKING

FOR TRACEABILITY, PART NUMBERS, BRANDING & BATCH IDENTIFICATION

WE MARK PARTS IN HOUSE FOR:

Part numbers, batch codes and traceability marks

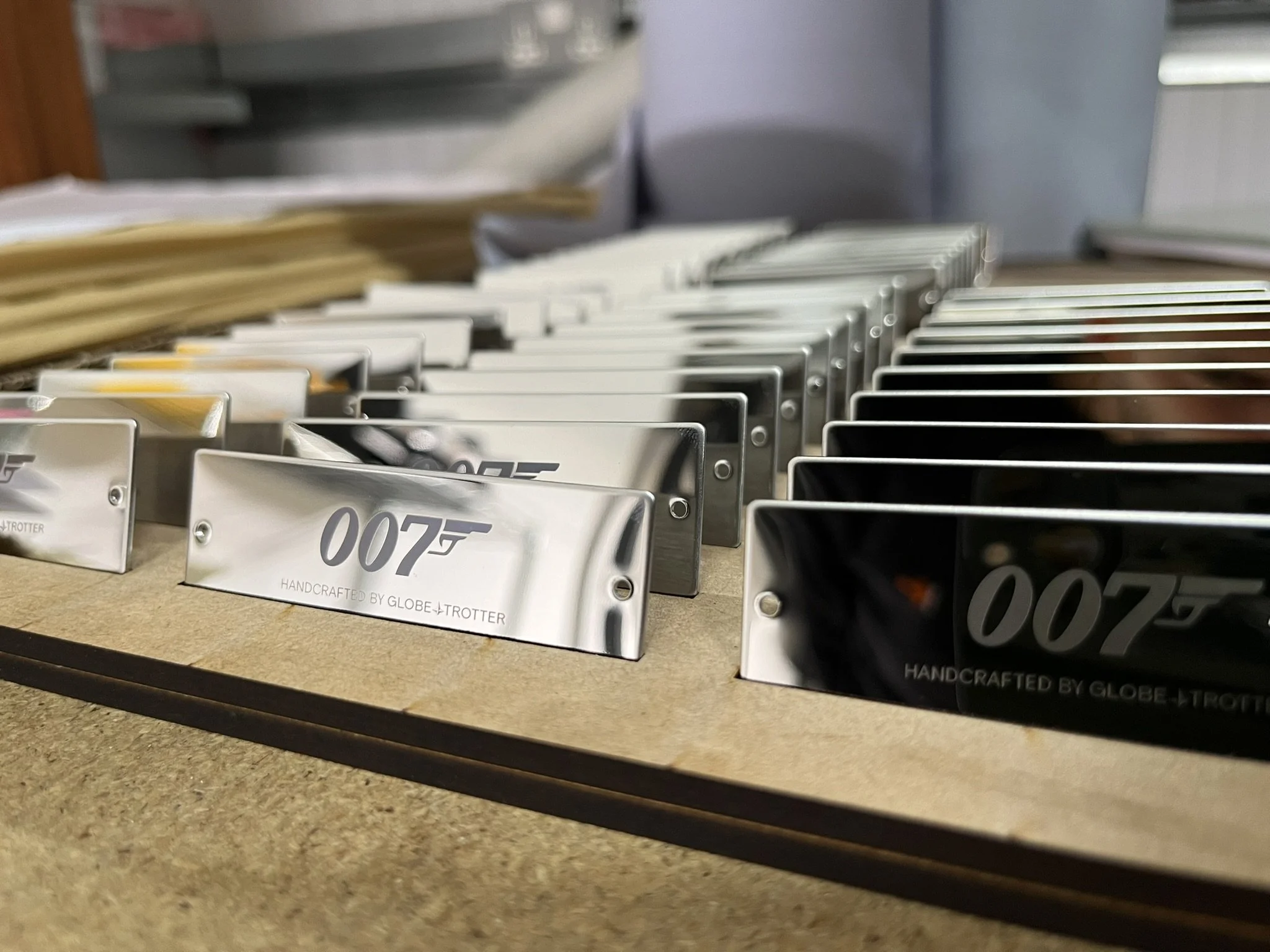

Logos, branding and product identifiers

QR codes and data matrix codes

Compliance information and serialisation

Hardware, lighting and product assemblies

Prototypes, small batch & repeat production

LASER MARKING CAPABILITIES

Laser marking is a non contact, permanent process using a fibre laser to alter surface appearance on metals and selected plastics without tooling or consumables. This makes it ideal for traceability, compliance and branding in manufacturing environments.

MATERIALS

We laser mark a range of metals, including aluminium, stainless steel, brass and titanium, plus selected industrial plastics. Marking can be done before or after surface finishes like anodising, plating or coatings.

TYPICAL APPLICATIONS

Part identification & serialisation

QR / data matrix and barcodes

Brand logos & product text

Compliance codes & regulatory marks

Traceability for batch production

Prototypes and one off parts

INDUSTRIES WE SUPPORT

Engineering & manufacturing

Electronics & enclosures

Automotive & motorsport

Medical & pharmaceutical

Lighting & hardware assemblies

Product development & OEM supply

AS FEATURED BY LOTUS LASER SYSTEMS

Lotus Laser Systems visited our workshop to film a feature on our fibre laser installation and how we use laser marking alongside CNC machining, prototyping and product development. The video shows how these processes work together to support UK manufacturers with prototype, batch and repeat production.

WHAT TO SEND

DRAWING OR CAD

Vector files (DXF, AI, SVG, PDF) preferred, especially for logos and text layouts.

PART DETAILS

Include part material, surface finish and part number if available.

QUANTITIES

Prototype, small batch or repeat production.

NOTES

Location of marking, text/logo details, font, QR content or serialisation scheme.

If you’re earlier in design or only have a concept, send what you have, we can advise and prepare your file.

LASER MARKING FAQS

-

Laser marking (also called laser etching or engraving) is a precise, permanent method of adding text, logos, or serial numbers to metal and plastic parts. It’s done using a high powered fibre laser that alters the surface without physical contact or cutting.

-

Yes, we can apply variable data such as unique serial numbers, QR codes and batch identifiers for traceability, compliance or inventory management. This is often used for hardware assemblies and repeat supply.

-

Yes. Laser marking is permanent, abrasion resistant, and does not wear off. It’s suitable for long life applications, harsh environments, and compliance with traceability standards.

-

Yes , our 60W fibre laser can mark on anodised aluminium, powder coated metal, and plated finishes without damaging the protective layer.

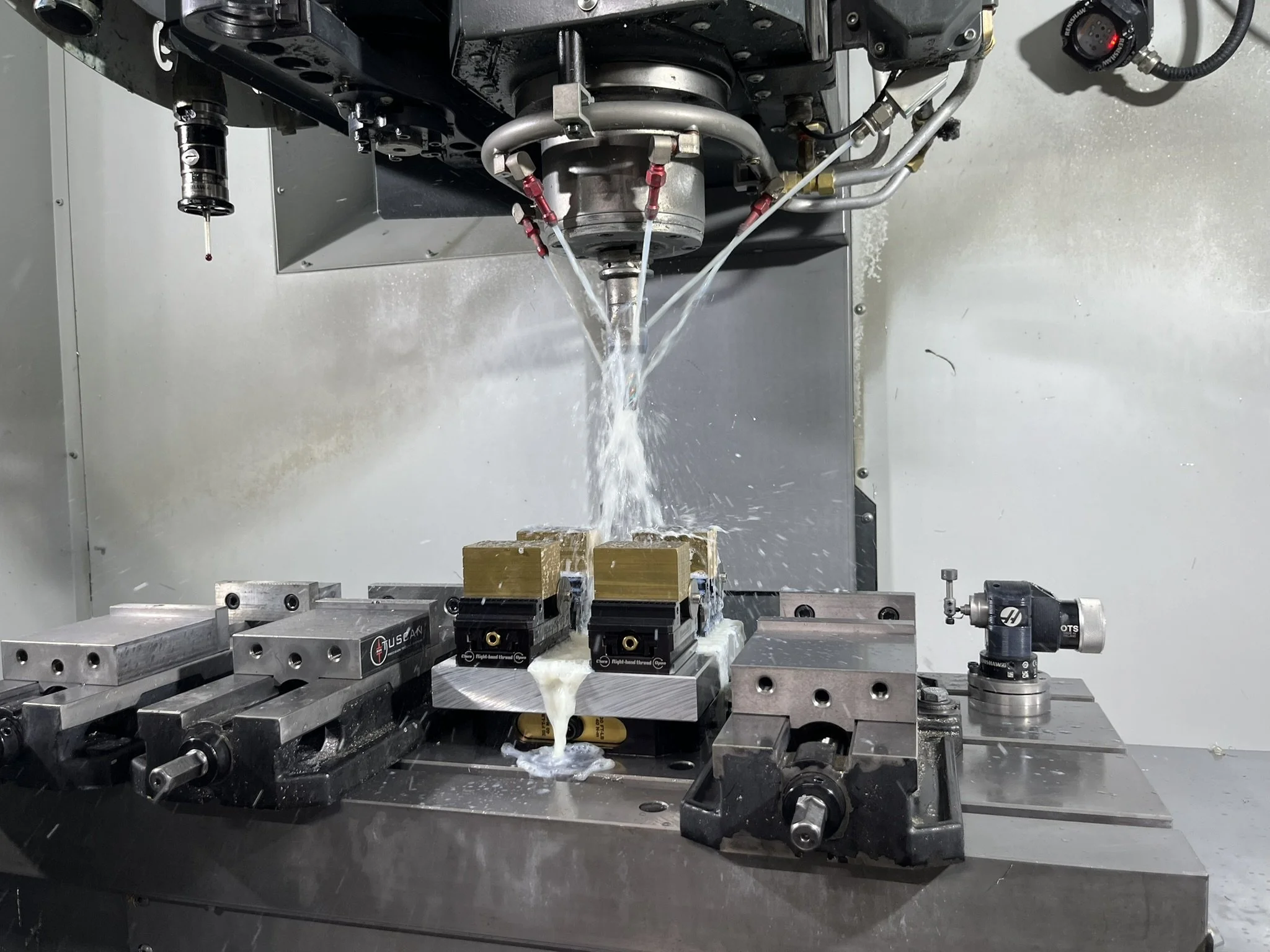

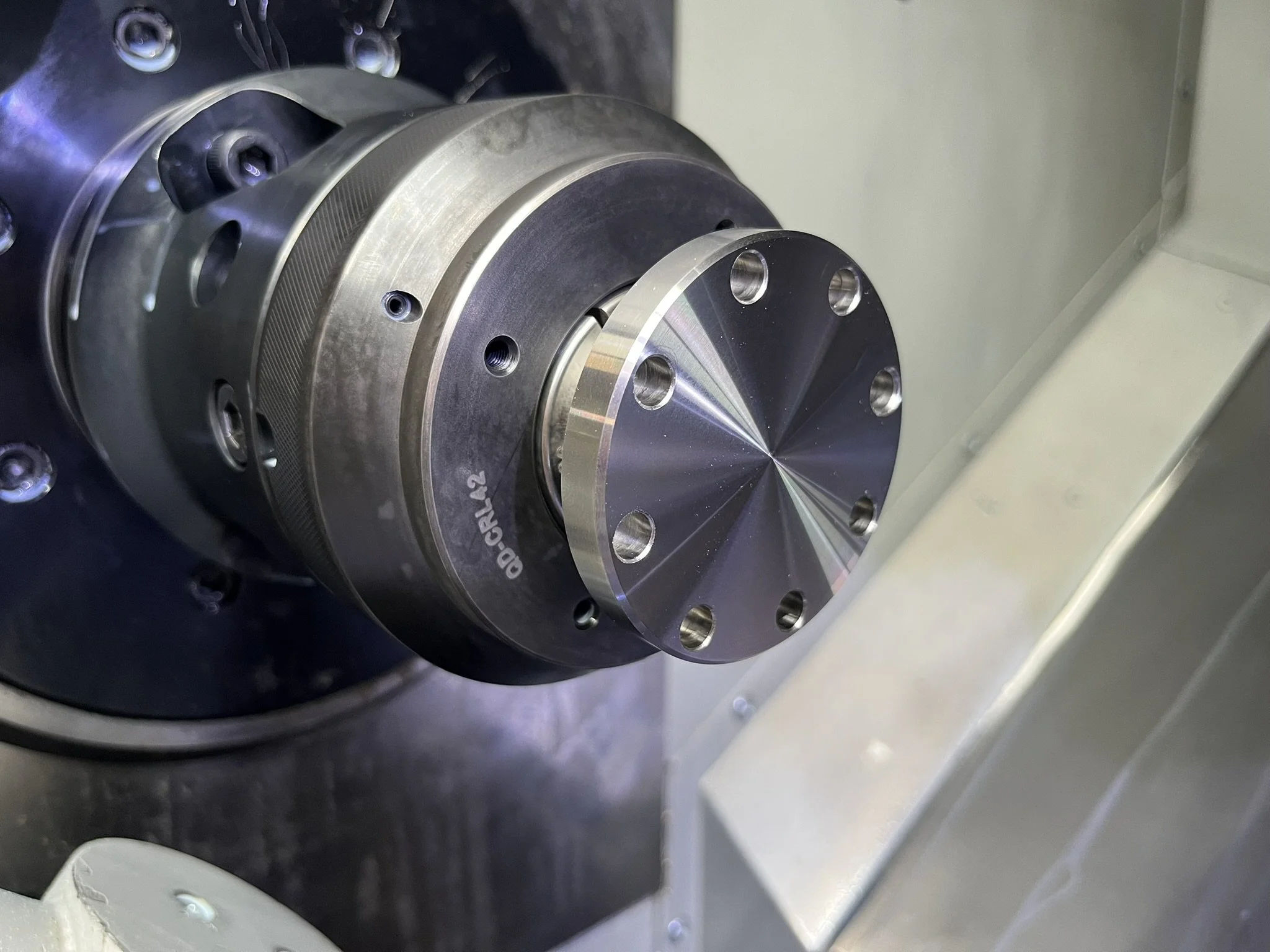

MORE UNDER ONE ROOF

Based in Hertfordshire, we provide laser marking, CNC milling, CNC turning, laser cutting and prototyping support for prototypes, small batch and repeat production across the UK.

Housings, brackets and development components for hardware and assemblies.

Round parts, shafts, spacers and fittings with threads and milled features.

Acrylics, foams and inserts for prototyping, packaging and assemblies.

For early concepts, iteration and testing before moving into batch production.

READY TO GET PARTS MARKED OR MACHINED?

Send us your drawing or CAD file, we’ll review it, ask any technical questions, and come back with next steps.