CNC MILLING

FOR PROTOTYPES, SMALL BATCH & REPEAT PRODUCTION RUNS

WE MACHINE PARTS IN HOUSE FOR:

Prototypes & development parts

Small batch production

Repeat batches for OEMs & manufacturers

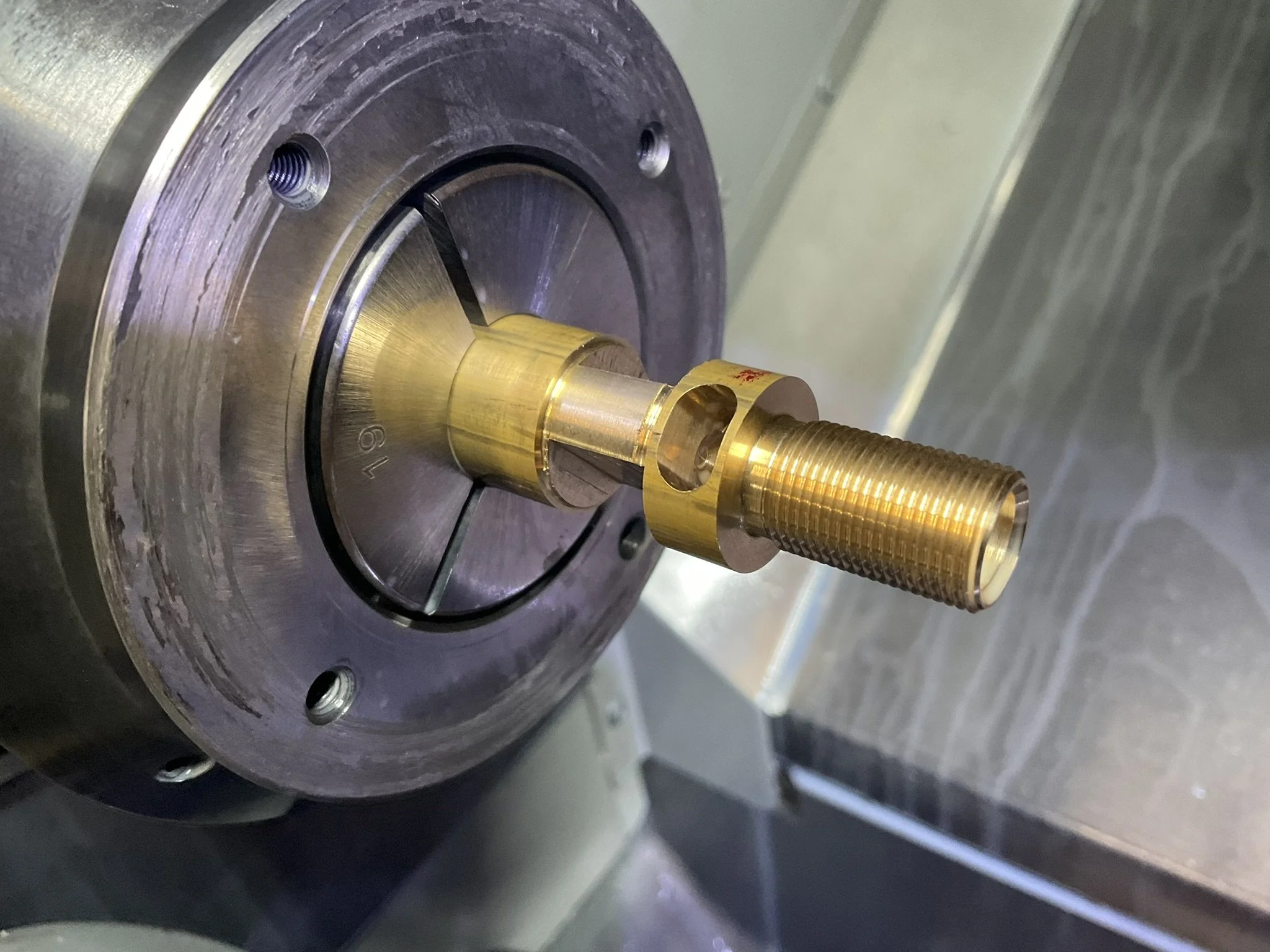

Aluminium, stainless, mild steel, brass & plastics

Tight tolerance & complex features

CNC MILLING CAPABILITIES

We machine a wide range of materials and part types in house, with finishing and repeat batches available.

MATERIALS

Aluminium, Stainless, Mild Steel, Brass & Plastics.

Suited for prototype and small batch work.

BATCH SIZES

Prototype, small batch & repeat production runs.

1–500 pcs typical (higher volumes on request).

PARTS WE COMMONLY MACHINE

Brackets, housings, mounts and prototype components for robotics, automation, electronics, lighting and product development.

FINISHING AND SECONDARY PROCESSES

Anodising, plating, bead blasting and laser marking. Custom packaging for repeat runs and batch dispatch.

WHAT TO SEND

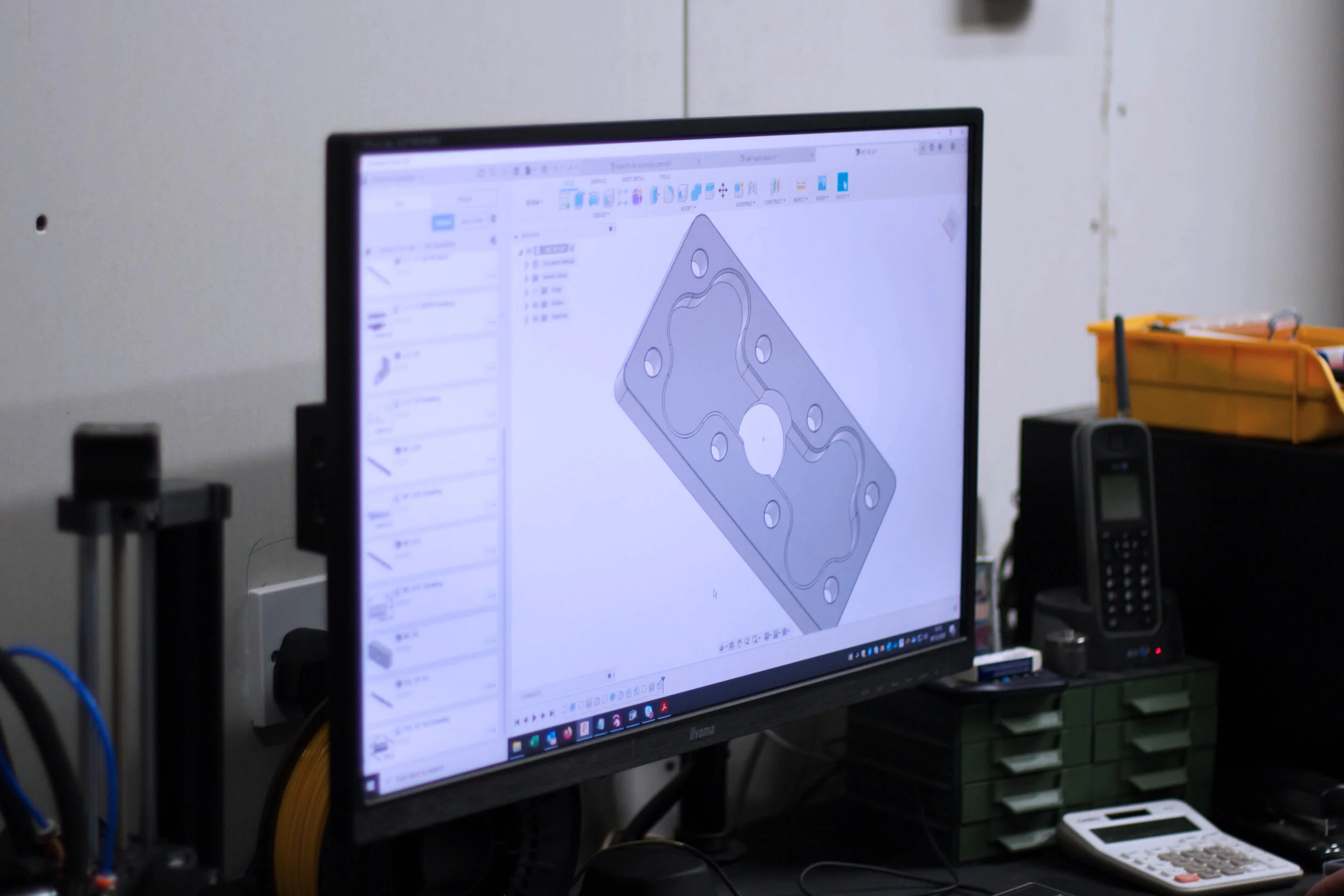

CAD FILES

STEP preferred

QUANTITIES

Prototype, small batch or repeat runs

MATERIAL

Aluminium, stainless, steel, brass or plastics

NOTES

Finishing, threads, tolerances or assembly info

If you’re earlier in the design process, feel free to send what you have, we’re happy to review.

USEFUL DETAILS FOR QUOTING & PRODUCTION

-

A drawing (PDF) is preferred for quoting as it gives us dimensions, tolerances, threads and finishing notes. STEP files are accepted for review or early stage discussion if drawings aren’t ready yet. Screenshots are fine for early conversations, but we’ll need a drawing or CAD to quote accurately.

-

We machine prototypes, small batch and repeat production runs. Typical quantities are 1–500 pcs depending on part type.

-

Yes - we regularly machine part families and mixed batches for hardware and product teams. Keeping related parts together makes development and repeat batches more consistent.

-

We’re a small workshop focused on making parts properly. You’ll speak directly with the engineers machining your parts, and we keep things straightforward, from early design conversations through to repeat supply.

-

Typical work includes brackets, housings and development components for robotics, automation, electronics, lighting and product development.

-

Yes - we support ongoing repeat work for OEMs and manufacturers, and keep packaging, setups and process notes consistent to make repeat orders straightforward.

-

Turnaround depends on material availability and batch size. Prototype jobs are often quicker than production batches. If you have a deadline, let us know when you enquire.

-

Yes - we regularly support engineers and designers during development. Early conversations often lead to better parts and smoother production runs.

MORE UNDER ONE ROOF

Based in Hertfordshire, we provide CNC milling, CNC turning, laser cutting, laser marking and finishing support for prototype, small batch and repeat production across the UK.

For projects with both milled and turned parts, we can machine everything in house to keep batches consistent.

CO₂ laser cutting for plastics and wood. Useful for inserts, panels and housings.

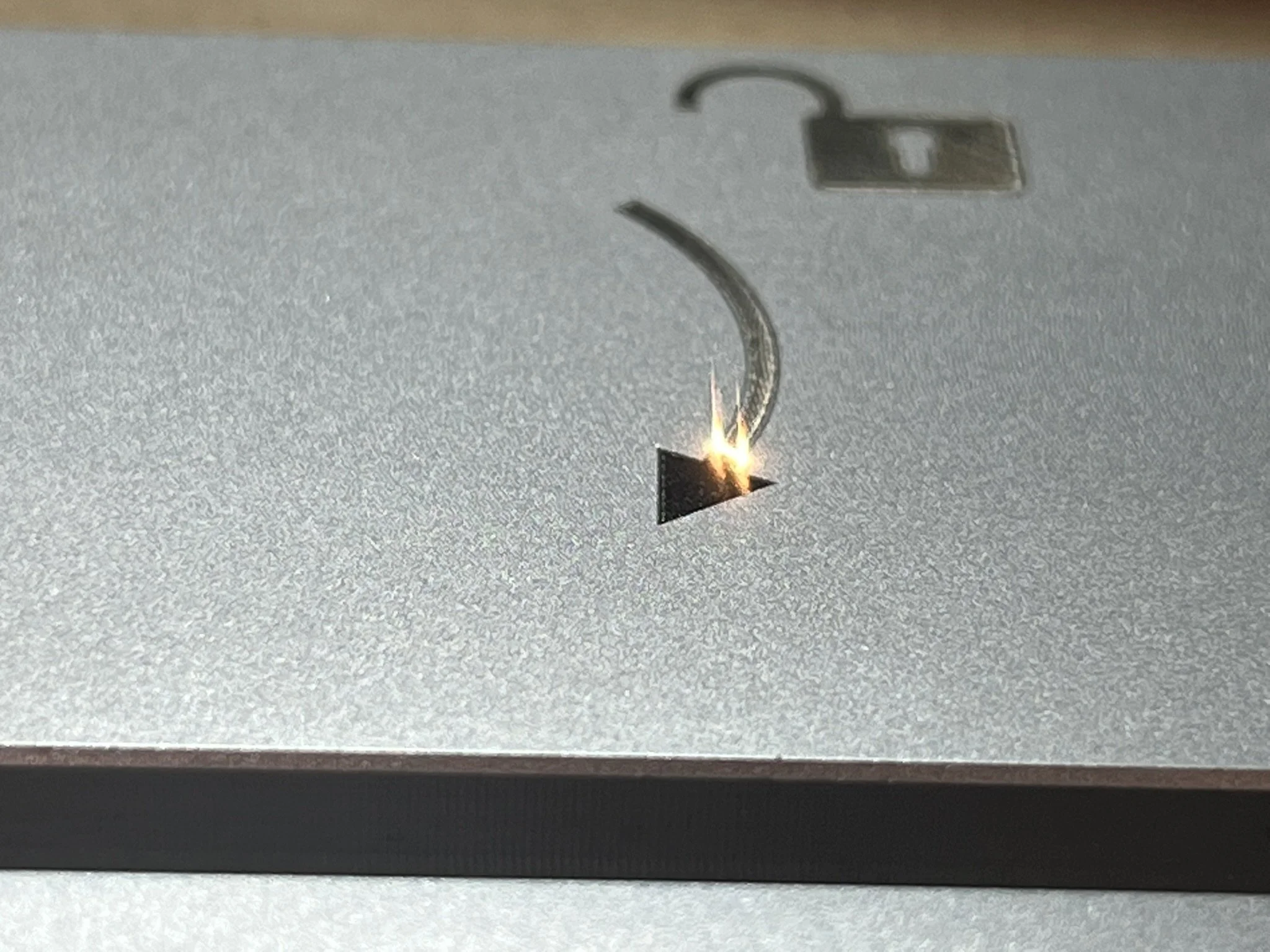

Fibre laser marking for part numbers, QR codes, traceability and branding, applied directly to metal and plastics.

We support early development with CAD and iteration, ideal for engineers and hardware teams.

READY TO GET PARTS MADE?

Send us your drawing or CAD file and we’ll review it, ask any questions, and come back to you with next steps.