LIGHTING

CUSTOM LIGHTING COMPONENTS & BESPOKE FIXTURE MANUFACTURING

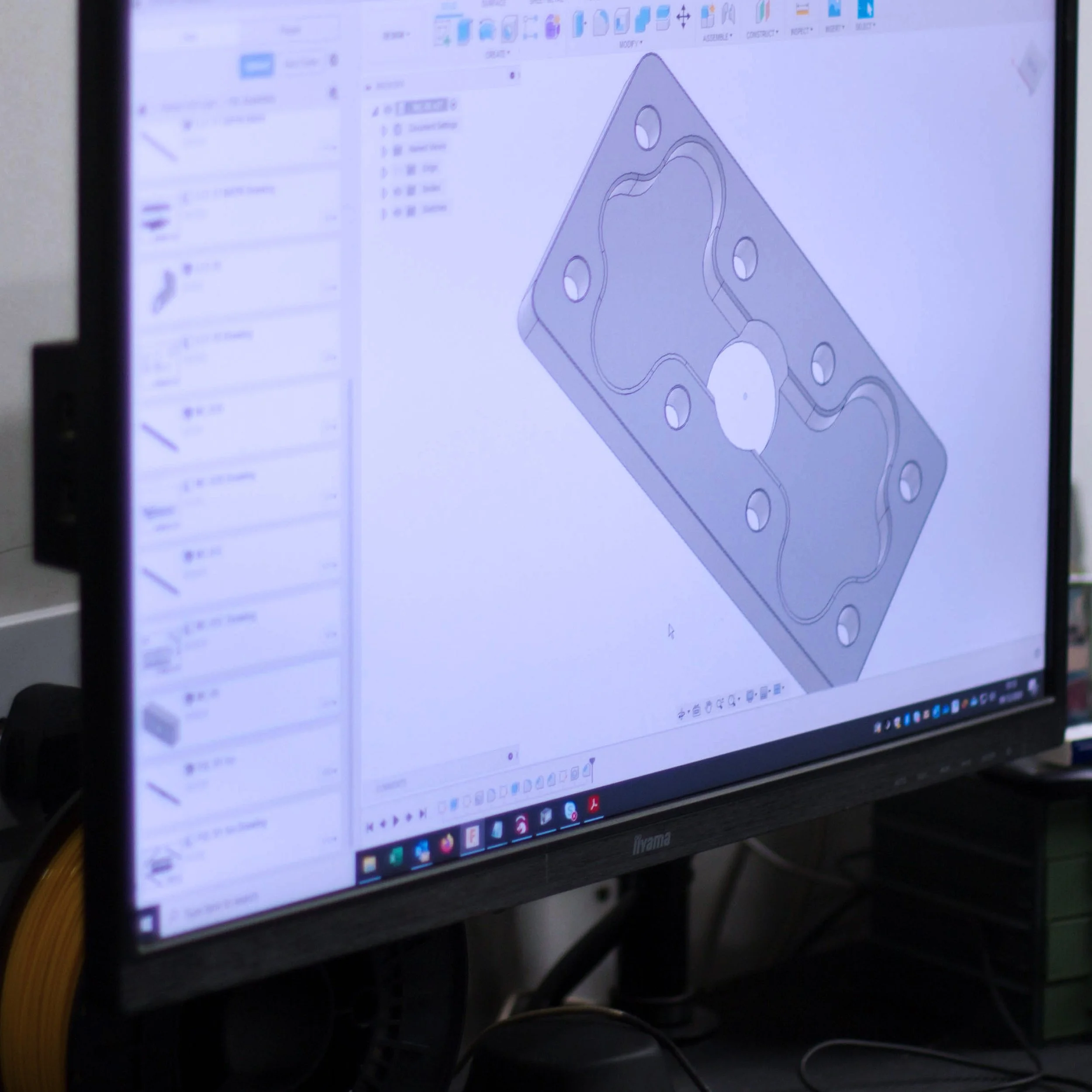

At Karpas Engineering, we specialise in the development and manufacture of custom lighting components and complete bespoke lighting systems - from concept through to final assembly.

We support clients across horticultural, residential, and architectural lighting, offering in-house CNC machining and prototyping for components such as ceiling roses, heatsinks, LED holders, and decorative fixings.

Whether you need one-off components for a bespoke chandelier or precision parts for a high-end production line, we offer LED sourcing, product development, and full assembly services tailored to your design.

HORTICULTURAL

LIGHTING

We manufacture CNC machined components for advanced LED grow lighting systems, supporting UK growers and commercial greenhouse operators. Our custom lighting parts are designed for controlled indoor environments, vertical farms, and research facilities.

These systems are built to optimise plant development across all growth stages - from rooting to flowering - with precision spectrum control and tunable colour temperatures. For high-value crops, our lighting supports maximum essential oil production, trichome density, and yield.

All components are engineered for long service life (50,000+ hours), thermal performance, and integration into single-source or supplementary horticultural lighting setups. We also support smart dimming, automation, and modular group control.

DECORATIVE & ARCHITECTURAL

We manufacture bespoke lighting components for premium decorative and architectural lighting projects across the UK. Working closely with lighting designers and high-end manufacturers, we produce custom parts for chandeliers, pendant lights, and one-off feature fixtures.

Our in-house services include CNC machining, LED sourcing, and assembly, ensuring every ceiling rose, connector, or mounting bracket meets the highest standards of fit and finish.

Whether it's a luxury residential installation or a commercial interior, we deliver detail-focused craftsmanship from concept to completion. Whatever it is, the way you tell your story online can make all the difference.

COMMERCIAL INDOOR & OUTDOOR LIGHTING

We supply CNC machined lighting components for a wide range of commercial and architectural lighting systems. From office interiors and retail environments to outdoor security and façade lighting, our parts are designed for reliability, precision, and clean integration.

We manufacture custom ceiling roses, mounting brackets, and control enclosures, built for fast installation and long-term performance in both indoor and exposed outdoor environments. Every component is produced in-house to meet the demands of high-traffic commercial settings and modern lighting design applications across the UK.

LIGHTING FAQS

-

We manufacture custom CNC machined components for lighting systems, including ceiling roses, heatsinks, LED mounts, brackets, and decorative fittings - all tailored to architectural, horticultural, and commercial applications.

-

Yes - we offer full support from concept to prototype, including CAD design, material selection, and precision machining. Our services are ideal for lighting designers and manufacturers developing new fixtures.

-

Absolutely. We can source high-performance LEDs and provide mounting solutions, cable management, and thermal considerations for complete lighting system builds.

-

Yes - we specialise in custom lighting components for high-end decorative and architectural lighting, including unique ceiling roses, connectors, and fully assembled statement pieces.

-

All machining, prototyping, and assembly is handled in-house at our workshop in Hertfordshire. This ensures tight quality control and short lead times for UK lighting projects.

-

Yes - we’re set up for one-off parts, small batch production, and short-run prototyping. Ideal for testing designs or fulfilling bespoke project requirements.

MORE WAYS WE CAN SUPPORT YOUR PROJECT

WE OFFER A FULL RANGE OF IN-HOUSE SERVICES TO COMPLIMENT YOUR PROJECT - FROM PRECISION MACHINING TO FINAL ASSEMBLY. EXPLORE:

High-precision turning with live tooling and Y-axis milling for parts that require both turned and milled features.

PROTOTYPING SUPPORT

We support early-stage development with CAD design, functional prototyping, and assembly - ideal for engineers, startups, and R&D teams.

Fast, accurate CO₂ laser cutting for plastics, wood, and thin metals - perfect for custom inserts, panels, and housings.

Fibre laser marking for logos, part numbers, QR codes and traceability - applied directly to metals and plastics with lasting results.

We machine, assemble, and support your lighting project from concept to completion.