PROTOTYPING & PRODUCT DEVELOPMENT

COMPLETE PROTOTYPING & PRODUCT DEVELOPMENT SERVICES

From concept to finished part, we offer a full suite of product development services - including CAD design, CNC prototyping, 3D printing, and assembly.

Whether you're developing a new product, refining an existing design, or producing one-off prototypes, we provide fast, practical engineering support tailored to your project. All work is done in-house at our Hertfordshire workshop, with close collaboration at every stage and short lead times across the UK.

THE PROTOTYPING PROCESS:

CAD DESIGN

We offer CAD design and engineering support to take your idea from sketch to fully manufacturable 3D model. Using advanced CAD/CAM software, we prepare your product for CNC machining, 3D printing, or full assembly - all from our Hertfordshire-based workshop.

CNC MACHINING

We produce precision prototypes and low-volume production parts using CNC Milling and CNC Turning. Whether you need aluminium prototypes, engineering plastics, or test components, we ensure tight tolerances and short lead times - right here in Hertfordshire.

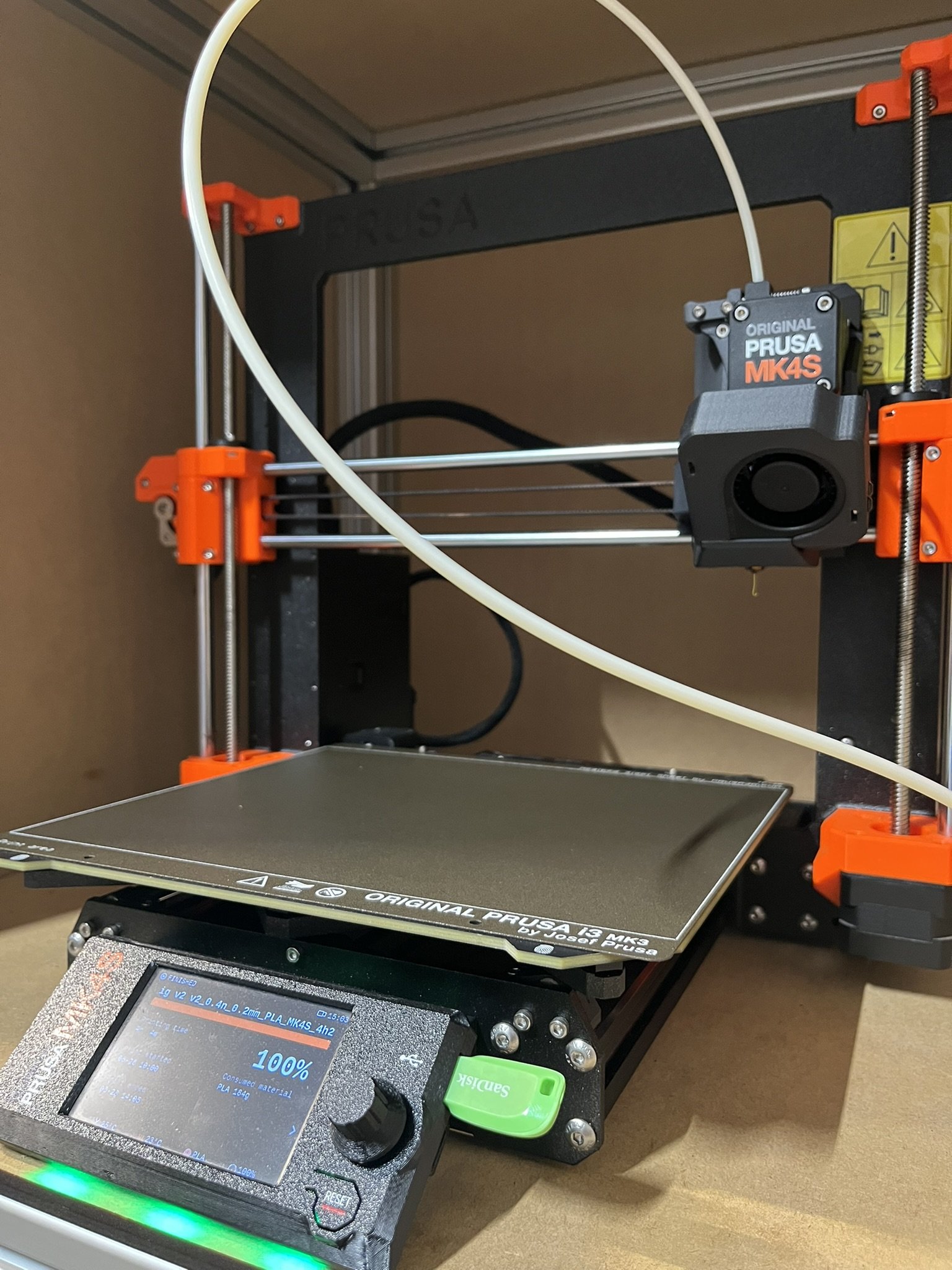

3D PRINTING

Our in-house 3D printing service allows for fast, cost-effective plastic prototypes. These are ideal for validating form, fit, and function before committing to production.

We use FDM printing to support product development, industrial design, and rapid prototyping projects across the UK.

ASSEMBLY

We provide light mechanical assembly, LED integration, and final finishing for complete parts and products. Ideal for Lighting, enclosures, and small assemblies - this optional service means you can receive fully built, ready-to-use components.

ADDITIONAL SERVICES TO COMPLETE YOUR PROJECT

WE ALSO OFFER:

Add part numbers, logos, or graphics to prototypes using our in-house fibre laser - ideal for identification, branding, or compliance requirements.

Protect and present your prototypes with precision-cut inserts made in-house using our laser cutting equipment. Ideal for shipping, product demos, or client-ready kits - and part of our full Laser Cutting services.

3D PRINTING EXPANDED-

FROM RAPID PROTOTYPES TO PRINT FARM PRODUCTION

We use in-house 3D printing for everything from rapid prototypes to high-volume production. Our print farm can handle large quantities of FDM-printed components with fast turnaround, making it ideal for product development, small-batch manufacturing, and scalable part supply. Whether you need one part or one hundred, we print with consistency and quality.

NEED TO GET SOMETHING 3D PRINTED? Send your file or idea — we’ll print it fast and accurately, in-house.

YOUR PROTOTYPING QUESTIONS ANSWERED

-

We produce a wide range of prototypes using CNC Machining, 3D printing, and laser-cut parts. Whether you need a functional aluminium prototype, plastic form model, or proof-of-concept assembly, we can help.

-

Yes - we specialise in fast-turnaround prototyping using in-house 3D printing and CNC machining. Our team can deliver parts quickly to keep your product development on schedule.

-

Absolutely. We offer CAD design support to turn your concept into a manufacturable 3D model, ready for CNC machining or 3D printing. We can work from sketches, drawings, or technical requirements.

-

We’re based in Welwyn Garden City, Hertfordshire, and ship across the UK.

-

We work with aluminium, engineering plastics (like acetal, nylon, PEEK), stainless steel, and brass. For 3D printing, we use durable materials such as PLA, PETG, and ABS.

-

Yes - we provide in-house assembly services including fasteners, wiring, LED integration, and more. This is ideal for lighting products, enclosures, and small mechanical builds.

-

We offer laser etching for part numbers, branding, or compliance markings directly onto your prototypes. Perfect for traceability or presentation.

-

Yes - we can create custom laser-cut packaging inserts for safe delivery or presentation. This is useful for shipping to customers or presenting samples at events.

Let’s talk - we help turn concepts into real, working parts.